Add to Cart

1. It has good fluidity and can improve the thickness, gloss,

hardness, and yellowing resistance of the paint film.

2. Insoluble in aliphatic hydrocarbon solvents and can be used in

gasoline-resistant coatings.

3. Used with chlorinated copolymer resin, PU resin, alkyd resin,

plasticizer, and other resins, suitable for coating wood, metal and

paper.

4. When used in baking paint formulations, it will not emit odor

and affect the gloss.

Run

The operating efficiency when used for softening treatment is determined by the following parameters:

a) The concentration and amount of the agent used;

b) The total hardness and content of the water being treated;

c) The flow rate of the inlet water flowing through the bed.

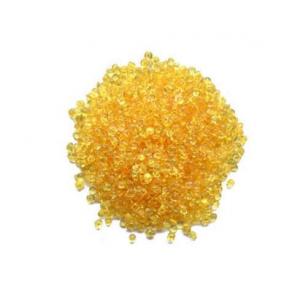

Low levels and high hardness removal results are required in the softening of tap water because acceptable water quality is obtained by operating through a spray steam system (in which raw water is blended with softened steam to produce tap water). In the brewing industry or food processing water preparation, the effluent water quality requires a hardness of less than 5 ppm, which can be obtained by using 70-80g of salt per liter of resin. [3]

Under normal operating conditions, the hardness leakage value is usually less than 1% of the total hardness of the incoming water, and the working exchange capacity is not affected, unless the Na+ (or its monovalent ion) ion content in the incoming water is too high and is greater than the exchangeable 25% of the total number of cations. Pressure drop is related to particle distribution, bed depth, exchange column void ratio, flow rate and fluid viscosity. Factors affecting these parameters will affect pressure drop.

Hydraulic properties

The pressure drop through the bed is usually affected by several factors such as the distribution of the resin, the height of the bed, the space of the ion exchange column, the flow rate of the incoming liquid, and the viscosity (related to temperature).

During backwashing, the resin bed will expand to between 50-75%. The purpose is to remove the solids brought by the incoming liquid and the gaps and bubbles in the exchange column, and redistribute the resin particles to obtain small resistance. When backwashing, the backwash flow rate should be gradually increased to avoid overloading due to impact on the resin. The bed expansion rate increases with the flow rate and decreases with the temperature, as shown in Figure 2. Be careful to over-extend to prevent resin from flowing out.

Chemical stability and temperature resistance

Purolite C-100E is insoluble in low and medium concentrations of acids, alkalis and general solvents. However, it should not be exposed to free chlorine, hypochlorite and other strong oxidants for a long time to reduce chain breakage, which will lead to high moisture content of the resin and reduced mechanical strength. Like styrene sulfonated resin, the salt type (sodium type or alkaline earth metal type) can withstand temperatures up to 150°C, while the acid type tends to hydrolyze above 120°C, and the sulfonic acid group is replaced by a hydroxyl group.