Add to Cart

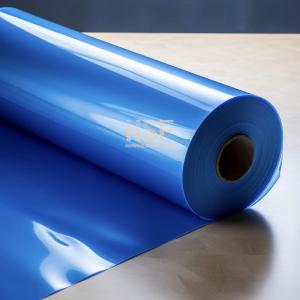

60 μm blue cast polypropylene film for food, medical can industrial packaging

60-micron CPP film in translucent blue or opaque blue is mainly used for heavy-duty packaging applications that require high puncture resistance and durability. Some of the primary application scenarios for this type of CPP film include:

1. Industrial packaging:

60-micron translucent blue or opaque blue CPP film is widely used in the industrial sector for packaging heavy-duty products such as

machine parts, equipment, and hardware materials. It provides excellent puncture resistance and durability, ensuring that the products are

well protected during transportation.

2. Agriculture packaging:

The strength, puncture resistance, and durability of 60-micron CPP film make it an excellent choice for packaging agricultural products

such as seeds, fertilizers, and soil.

3. Construction packaging:

The film is used for packaging construction m1aterials such as cement, sand, and gravel. Its high weight carrying capacity and superior

strength ensure that the products are well protected during transportation and storage.

4. Heavy machinery packaging:

The film is used to pack large and bulky items such as heavy machinery, industrial equipment, and automotive parts. Its superior puncture resistance and durability provide excellent protection against damage during transportation.

5. Large-scale electrical appliances:

CPP film is used to wrap large-scale electrical appliances such as air conditioners and refrigerators. The superior strength and puncture

resistance properties of the film protect these items during transportation and storage.

Overall, 60-micron CPP film in translucent blue or opaque blue is ideal for packaging heavy-duty and bulky items that require superior strength, puncture resistance, and durability.

CPP film (Cast Polypropylene film) differs from OPP (Oriented Polypropylene) or BOPP (Biaxially Oriented Polypropylene) films in several ways:

Manufacturing Process:

CPP film is produced through the cast film extrusion process, where

molten polypropylene is extruded onto a casting drum and then

cooled to form a continuous film. On the other hand, OPP and BOPP

films are manufactured through the biaxial orientation process,

involving stretching the film in both the machine direction (MD)

and transverse direction (TD) to enhance its mechanical properties.

Clarity and Gloss:

CPP film typically exhibits better clarity and gloss compared to

OPP or BOPP films. It offers a high level of transparency, allowing

for excellent product visibility in packaging applications.

Sealing Properties:

CPP film generally provides better sealing properties than OPP or

BOPP films. It has higher seal strength, making it more suitable

for applications that require reliable heat sealing, such as food

packaging.

Heat Resistance:

CPP films typically have higher heat resistance than OPP or BOPP

films. This property makes CPP films well-suited for applications

involving hot-fill or retort packaging, where exposure to high

temperatures is required.

Puncture Resistance:

CPP films generally offer higher puncture resistance compared to

OPP or BOPP films. This increased resistance to punctures, tears,

and abrasions makes CPP films more durable and better able to

withstand rough handling during transportation and storage.

Processing Characteristics:

CPP film has good dimensional stability, meaning it is less prone

to shrinkage or stretching during processing or use. This

characteristic helps ensure consistent packaging performance.

Additionally, CPP film has good stiffness, which contributes to its

ease of handling and processing.

Printing and Graphics:

CPP film has excellent printability and allows for high-quality

graphics and branding elements on packaging. Its clarity enables

vibrant and visually appealing designs.

Overall, CPP film offers advantages such as improved sealing properties, enhanced clarity, higher heat resistance, greater puncture resistance, and good processing characteristics when compared to OPP or BOPP films. These properties make CPP films a preferred choice for various packaging applications in industries like food, cosmetics, industrial, and medical packaging.

| Test Item | Unit | Range | Test Standard | |

| Thickness | Avg. | μm | 60 | GN/T 6672 |

| Max. | ≤64 | |||

| Min. | ≥56 | |||

| Width | Avg. | mm | 1020 ±3 | GN/T 6673 |

| Tensile strength | MD | MPa | ≥20 | GN/T 1040.3 |

| TD | ≤15 | |||

| Elongation @ break | MD | % | ≤300 | GN/T 1040.3 |

| TD | ≤300 | |||

| Wetting tension | - | mM/m | ≥38 | GN/T 14216 |