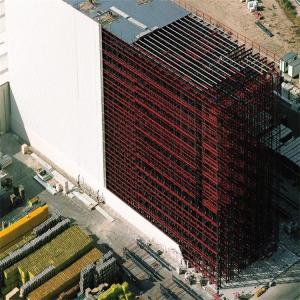

Clad rack buildings with automated systems and robotic equipment

for the handling of goods

Clad Rack Warehouses can be made up of any type of storage system

as their main feature is for the racking to form part of the

building structure.

In this system, the racking not only supports the load of the

stored goods, but also the load of the building envelope, as well

as external forces such as wind or snow.

Advantages:

1.Full use of the surface area

the warehouse is designed at the same time as the racks and only

occupies the space required, without intermediate pillars that

influence their distribution.

2.Optimisation of height

as with the surface area, the height will be only that which is

required. At the same time, the upper trusses or girders require

less height and incline being directly supported on the racking.

3.Maximum height of the construction

You can build to any height, it only depends on local regulations

or the scope of the handling means which are used, being able to

exceed 45 m high (which would be complex and expensive in

traditional construction).

4.Simpler construction

The entire structure is assembled on a concrete slab of suitable

thickness to achieve uniform distribution of the forces on the

foundation; there isn’t a high concentration of loads.

5.Less time for completion

Once the slab is built, the entire structure and cladding are

progressively and concurrently installed.

6.Cost savings

As a general rule, the cost of a clad-rack warehouse is less than

the more traditional racks. The greater the construction height,

the more profitable the clad-rack system.

7.Minimal civil works

it only requires the construction of the slab on the ground and, in

some cases, a waterproof wall between one and two metres high. In

which case the operations area needs to be expanded for receipt and

dispatch, a traditional

building can be built, but of sufficient height without reaching

the total height of the warehouse.

8.Easily removable

Being a structure formed by standard rack elements that come

pre-assembled or bolted, they can be dismounted with ease and a

high percentage of components recovered.

| Product name | Self supported buildings |

| Material | Q235/355 Steel |

| Certification | ISO9001,CE |

| Design | AutoCAD |

| Length | Customized |

| Width | Customized |

| Finished | Power coated |

| Used | industry normal warehouse, cold storage, auotamed warehouse |

Product Display:

Union Mezzanine floor upright and Beam section:

Certificate

CE, ISO

Our Exhibition

Q&A

1.I am intersted in self supported, but I am not that professional,

whatshould we do firstly?

Firstly, you give your area size, tell us your requirement for

layers and loading capacity for us to make design

2. What is your warranty?

1 year guarantee for free accesssories and 10 years for the rack

will not fall.

3. Do you support installation?

We provide all sets installation drawing, you can choose find

installation team yourself or we find, our enginner can arrive on

site for guidance.

4.What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange

30%deposit→Manufacture→QC inspect→Pay balance→Shipping

5.What’s your advantage?

1) Factory price: factory direct sale competitive price.

2)Static Calculation for Seismic Factor

3)Competitive Design&Structure Manufacturer

4)FreeConsultationon StorageSolutions