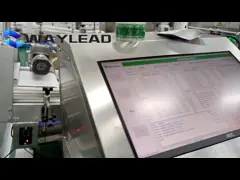

hffs horizontal flow wrapping machine

The HFFS (Horizontal Form Fill Seal) horizontal flow wrapping system utilizes flexible plastic or composite films to automate product packaging by simultaneously performing forming, filling, and sealing operations. By employing continuous motion technology, this system enables swift packaging cycles while ensuring precise seal integrity.

Product Applications:

• Food Industry: Manages snacks, frozen items, and fresh produce while adhering to stringent hygienic sealing standards.

• Pharmaceuticals: Ensures tamper-proof packaging for medical products.

• Retail Products: Processes cosmetics and household goods, providing visually appealing packaging finishes.

• Agricultural Items: Offers durable protection for agrochemicals and seeds.

Product Advantages

• Operational Efficiency: Capable of handling up to 200 packages per minute based on product specifications.

• Material Versatility: Supports various multi-layer films, including PET/AL/PE composites.

• Quality Control: Maintains consistent wrap tightness through integrated tension management.

• Space Efficiency: Horizontal design minimizes the space requirements of the production line.

System Components

Film unwinding and forming module

Precision filling station

Multi-seal jaw assembly

Programmable logic controller

Common packaging materials for hffs horizontal flow wrapping machine:

The HFFS horizontal flow wrapping machine is capable of utilizing a diverse range of packaging materials. However, the optimal choice of packaging material hinges on the characteristics and specifications of the item being packaged. Here are several common packaging materials well-suited for deployment on the HFFS horizontal flow wrapping machine:

Film:

Film stands out as a prevalent choice for HFFS packaging machines. Various film types such as polyethylene (PE), polypropylene (PP), polyester (PET), and others can be selected based on the product's composition.

Composite Film:

Composite film, composed of two or more distinct materials, offers superior moisture resistance, oxidation protection, and preservation capabilities. It proves ideal for safeguarding products susceptible to environmental influences.

Heat Shrink Film:

Heat shrink film contracts upon heating post-packaging, ensuring a tighter seal. This material finds utility in packaging bottled beverages, cosmetics, and similar items.

Paper-Plastic Composite Material:

Combining the aesthetic appeal of paper with the moisture-resistant attributes of plastic, paper-plastic composite material is fitting for packaging delicate gifts or food items.

Environmentally Friendly Materials:

Environmentally friendly options like biodegradable substances and recyclable materials are viable choices if they align with product requisites, meeting contemporary consumer demands for sustainable packaging.

Special Functional Film:

Specialized films like antistatic, anti-ultraviolet, and anti-slip variants cater to distinct product requirements. Select the appropriate functional film in accordance with specific product needs.

When selecting packaging materials, beyond product considerations, factors like visual appeal, freshness retention, barrier properties, recyclability, and more should be taken into account. This holistic approach ensures that the resultant packaging aligns with product specifications, enhancing packaging quality and market competitiveness.

.

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we provide quality products at factory price, welcome to visit us!

Q2: If we buy your machine, what quality guarantee or warranty do you provide?

A2: We provide you with high-quality machines with a 3-year warranty and provide lifetime technical support.

Q3: When can I get the machine after payment?

A3: The delivery time is subject to the exact machine you confirmed

Q4: How do you provide technical support?

A4:1. Provide technical support via phone, email or MSN/Skype 24/7

2.Provide you with instructions/videos for machine installation, adjustment, setting, maintenance.

3. Engineers are available to provide services for overseas machinery

Q5: How does your after-sales service work?

A5: Ordinary machines will be properly adjusted before shipment. You can use the machine immediately. You can also get free training advice on our machines in our factory. You can also get free advice and consultation, technical support and service, and lifetime technical support via email/fax/phone.

Q6: How about spare parts?

A6: After we handle everything, we will provide you with a spare parts list for your reference

Q7: If we have very special requirements for the production line, can you help me with the design?

A7: Customized design is available with experienced mechanical engineers

Q8: If we have samples of new products, can you help analyze and design the machine?

A8: Yes, our technical department can help analyze, design and test the new products you provide.

Q9: Can you tell me how to start an order?

A9: After paying a 30% deposit to our company after signing the contact information (Pl). We arrange production. Test and inspect the machine before shipment. Checked by customers or third-party agencies through online or on-site testing. Send the balance before shipment

Q10: Can you send me the product catalog and price list?

A10: An electronic catalog showing product styles is available for your reference. Since the prices of specific products vary, please consult us for your detailed products

Q11: Can l visit your factory?

A11: Sure, Our factory address: Room 304,Wanchuangfang, No.155 Anzhi Road, Jiading District,Shanghai,China