Add to Cart

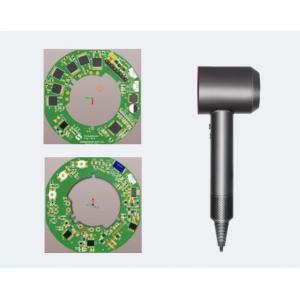

PCBA with full-bridge IPM for Hair Dryer with High pressure, high speed, non-inductive FOC

In the high voltage, high speed and non-inductive FOC hair dryer full bridge IPM solution, full bridge IPM stands for full bridge Integrated Power Module. Full-bridge IPM is a modular electronic component that integrates the functions of power switching components, drive circuit and protection circuit required by full-bridge topology.

Full-bridge IPM is commonly used in high-power and high-voltage applications such as brushless motor drives, inverters, and power systems. It is designed to provide efficient, high-performance power conversion capabilities and reduce the number of external components in the system and the complexity of the connection lines.

In the high voltage and high speed non-inductive FOC full bridge IPM solution, the full bridge IPM is responsible for driving and controlling the power switching devices in the full bridge topology. The full bridge topology consists of four power switching components (usually MOSFET or IGBT) and their accompanying drive and protection circuits. By controlling the switching state of these power switching devices, high voltage and high speed non-inductive FOC control of brushless motors can be achieved.

Full-bridge IPM offers many advantages, including compact package, low resistance, low inductance, high efficiency and high reliability. By using full bridge IPM, you can simplify circuit design, improve system integration, and provide better circuit protection and thermal management capabilities, thereby improving the performance and reliability of high voltage and high speed non-inductive FOC hair dryer solutions.

| Description | Capability |

| Motor type | Brushless motor |

| rotate speed | 100000rpm |

| Protection Functions | Over current, over pressure, over temperature, tuyere and other protection |

| Application | three-phase brushless motor products |

-- Highly integrated main control SOC chip, multi-channel op amp, comparator, high-speed ADC, etc., streamline peripheral circuits.

-- Non-inductive FOC control, dual resistance sampling.

-- Constant power ring or speed ring control, integrated temperature control, gear control, display function, negative ion generation control and other integrated solutions.

-- Start fast acceleration, speed up to 100000rpm, strong wind, blockage detection.

-- Over current, over pressure, over temperature, tuyere and other protection, fully through the mass production level functional performance test.

-- It is suitable for three-phase brushless motor products such as high-speed hair dryer.