Add to Cart

Smooth Geomembran | ||||||||||||||

Item | Index | |||||||||||||

The thickness(mm) | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 | |||||||

The density(g/cm3) | ≧0.94 | |||||||||||||

Tensile yield strength (longitudinal and transverse)N/mm | ≧11 | ≧15 | ≧18 | ≧22 | ≧29 | ≧37 | ≧44 | |||||||

Tensile break strength (longitudinal and transverse)N/mm | ≧20 | ≧27 | ≧33 | ≧40 | ≧53 | ≧67 | ≧80 | |||||||

Elongation at yield (longitudinal and transverse)% | ≧12 | |||||||||||||

Elongation at break (longitudinal and transverse)% | ≧700 | |||||||||||||

Right-angle tear resistance (longitudinal and transverse)N | ≧93 | ≧125 | ≧160 | ≧190 | ≧250 | ≧315 | ≧375 | |||||||

Puncture resistance N | ≧240 | ≧320 | ≧400 | ≧480 | ≧640 | ≧800 | ≧960 | |||||||

Stress cracking under tensile load (dead-load tensile method with

notch)h | ≧300 | |||||||||||||

Carbon black content% | 2.0~3.0 | |||||||||||||

Oxidative induction time(OIT) min | Induction time of oxidation at atmospheric pressure≧100 | |||||||||||||

Induction time of high pressure oxidation≧400 | ||||||||||||||

85℃ thermal aging (OIT retention rate at atmospheric pressure after

90 days) % | ≧55 | |||||||||||||

Uv resistance (OIT retention rate after 1600h UV irradiation) % | ≧50 | |||||||||||||

item | value |

Type | Geomembranes |

Warranty | More than 5 years |

After-sale Service | Online technical support, Free spare parts, Return and Replacement |

Project Solution Capability | graphic design |

Application | Outdoor |

Design Style | Modern |

Place of Origin | China |

Shandong | |

Brand Name | LuXin |

Model Number | GH-2S |

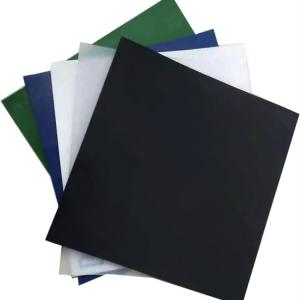

Color | Black |

Material | High Density Polyethylene EVA |

Product Name | Smooth Geomembrane |

Keyword | HDPE Geomembrane Waterproof |

Thickness | 0.2mm-2.8mm |

Surface | Double Smooth |

Length | 50-200m |

Width | 1-6m |

Standard | ASTM GRI-GM13 |

Certification | CE/ISO9001 |