Add to Cart

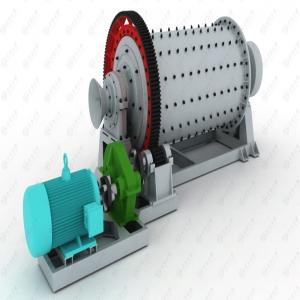

CE Superfine Ball Mill Classifying Production Line for silica powder,Gypsum, Glass, Cement Clinker, Ceramic, etc for quartz , felspar ,calcite , marble , carborundum , ,sand etc. (For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

2. Specifications

3. Working principle

Working Principle of Superfine Ball Mill Grinding Production Line GMF:

4. Technical Parameter

5. Features of GMF Superfine Ball Mill classifying Production Line

:

1. Low energy consumption: GMF superfine ball mill production line

adopted high advanced energy-saving technology and classification

technique; as a result, our production line can save over 40%

energy for producing same quantity materials.

2. Several times of classification could be obtained:

Finished product fineness after classification: 120-200mesh,or

200-325mesh,or 325-2500mesh,or 2500- 6,250mesh (d97≤2um).According

to customer requirements.

3. Adopted highly advanced self-diffluent classification system:

4. Scientific grinding medium enable us to produce large quantity

superfine particles.

5. Different lining boards and grinding mediums are available for

milling different materials, so as to guarantee the purity and

whiteness of finished products.

6. Scientific machine structure enables a lower investment cost;

7. Low failure rate and stale operation: because our ball mills and

classifiers in the production lines are PLC controlled and have

high automation;

8. Negative pressure production condition gives a good production

environment;

9. High annual production capacity: 5-500 thousand tons.

6.Product Details

7. Customer Case

8. Application

(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

1.Equipment painting completed before shipment, With Stretch film to avoid rub off the surface paint, It can used wooden cases packaging according to users requirements.(Key parts such as electric cabinet with shockproof packaging material and then packed in wooden cases. )

2. We have 15 experienced engineers, With 108 skilled workers insure good quality of our machines and prompt delivery.

3.Meanwhile our company has a long-term cooperation with ACL, CSCL, CCNI,CNC, COSCO etc insure the goods to the port on time.

1.What main products do you supply?

2 . Are you a trading company or factory?

3 Delivery date for my order?

4 How about your payment methods?

5. How do you handle the shipment for my order?and Packing?

6. What is your company warranty policy?

7. Do you offer any replacement for my order?

8. How can I contact to you?

Weifang GUOTE Mine Equipment co.ltd. is professional and modern enterprise including research and development, engineering design, production and installation, debugging services , automatic control equipment, non-metallic mineral production line test, design, consultation and the complete line of delivery.The scope of services related to mining, metallurgy, electric power, coal, glass, paper, chemical building materials, refractory materials, tiles,food, cement ,etc.Our product sell well in more than thirty provinces, autonomous region.(For details, please contact me:Annie Chang,Mob:0086-18678029069(whatsapp),E-mail: Annieflower.chang dot sdguote.com)

Our product have electromagnetic, permanent magnetic separator, dry

wet magnetic separator,electromagnetic vibration feeder, quartz

sand making machine, air classifier, dust collector, water

separator, washing machine, flotation machine,metal detector, screw

conveyor, timing quantitative feeding,weigher and centralized

control system, etc.

Facing the new opportunities and challenges, the company in line

with the spirit of "honesty-oriented, mutual benefit, cooperation

and innovation" , dedicated to providing “dependable,simple and

efficient” products and services to customers, make enterprises

become domestic advanced mining equipment manufacturer.

Our company is willing to work together with people from all walks

of life for a better future.

We could make whole production line or single equipment following

different clients requirements.

For whole process as below:

Firstly, Please offer detailed technical drawing in CAD or

requirements. Secondly, we will offer different technical proposals

follwing offered drawings or requirements for clients. Thridly make

decision for which proposal.At last manufacture whole equirements

following techncial proposal and holding test in warehouse. Finally

finished equipment/prodcution line offered as turn-key project.

For details, please contact :

Annie Chang ,Mob: +8618678029069(WhatsApp/wechat)

Skype:anna1983cyj ,QQ:896247401

Email:annieflower.chang at sdguote.com

website: https://sdguote.cnen.alibaba.com/

If you have any questions, pls don't hesitated to contacting me

anytime.