Add to Cart

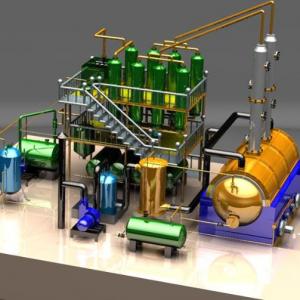

Model:ZL-9

Raw

material:Waste tireplastic ubberengine oil

Structure:HorizontalVertical

24hours processing capacity:15-20tons raw materials

24hours oil output:13.5-18tons diesel

Work pressure:Negative pressureVacuum

Host dimensions:φ2000*5000

Power:25.0KW

Cooling:Water cooling

Lose water(TD):5

Heating method:DirectlyAuxiliaryElectric heating

Noise dB(A):≤85

Working form:Continuous

Installation:Have basis Installation area:150square meters

Manufacuring time:20days

1 Successive mass transfer area, gas-liquid two-phase full contact.

2 Two-phase separation effect is good.

3 Gas and liquid phase through the ability of large units per unit

of equipment production capacity.

4 Operation flexibility, can be in the larger gas-liquid range to

maintain a stable operation, easy to control, easy to operate, high

efficiency.

5 Fluid flow resistance is small, energy loss is small, cost

savings.

6 Simple structure, reliable, low investment costs.

7 Easy to install and repair and clean.

The vacuum distillation equipment introduced by our company has

fundamentally solved the difficult problem of the small refining

industry.

Model | Raw material | Structure form | Cooling system |

ZL-9 | Waste rubberplastic yre oil | Horizontal Vertical | Water cooling |

Heating method | 24hours handling capacity | Power | Installation |

DirectlyAuxiliaryElectric heating | 15-20tons raw materials | 25.0KW | Have basis |

1, To improve the quality and functions of products is our purpose, customer's satisfaction is our principle.

2, With fast and practical feed and slag system.

Efficient gas heating system.

3, stable product quality , supply, the lifetime after sale.