Add to Cart

Sieve plate is easy to penetrate, having good wear-resisting and

corrosion resistance. With cross-section, even gap,stable welding

quality, large opening area, long life time, high strength and high

load capacity, it can be made into various shapes. The dimensions,

wire diameter, slot and frame structure can be customized.

Application: mining, coal separation, drilling, fertilizer, food,

environmental protection, metallurgy, medicine and other

industries.

Specifications

Diameter (mm) | Φ20, Φ50, Φ53, Φ57, Φ60, Φ65, Φ70, Φ75, Φ80, Φ100, Φ125, Φ200, Φ245, Φ300, Φ320, Φ360, Φ400, Φ450, Φ500, Φ550, Φ600, max. 1200 |

Slot (mm) | 0.010, 0.015, 0.02, 0.05, 0.1, 0.15, 0.2, 0.25, 0.3, 0.5......15 ... |

Length (mm) | 50~6000 |

Material | stainless steel (AISI 304, 316, 316L...), low carbon steel, low carbon steel galvanized zinc, steel treated with plastic spraying |

Note | Non-standard offer, can be produced as per request |

Specification:

1. Material: Carbon steel, Low carbon steel, Stainless steel

(304,316L,1Cr18Ni9Ti,0Cr18Ni9,00Cr17Ni14Mo2,321) Duplex stainless

steel,Hastelloy, Titanium alloy,etc

2. Minimum slot size: can be up to 8 microns.

3. Wrap and support rod: Wrap type: V1,V2,V3,V4; Rod type:

V4,V5,V6,T1,T2,U1,U2

4. Note: The length and width can be customized.

Pressure bend sieve is a kind of high efficient sieve, relying on

pressure screening the wet, which is composed of screen surface,

sieve box, feeding device and outlet. The screen surface is the key

component. It is made of stainless steel shape screen. When

operating the wet material ejected from the nozzle under pressure

from 0.2 to 0.4 Mpa, high ejection speed produces tangential force,

triangular mesh wedge forms blade to scrap the material into a thin

layer, then the water and fine material evenly dispersed,and the

entire screen surface get essential self-cleaning. The material on

the sieve discharged from the taphole,The material under the sieve

get into the stock inlet. As it adopted the multistage

countercurrent washing process, it can effectively improve powder

extraction rate and starch quality, having an obvious economic

benefits. It becomes an replacement of the screening process in

starch industry.

Application: germ washing and fiber separation in starch industry.

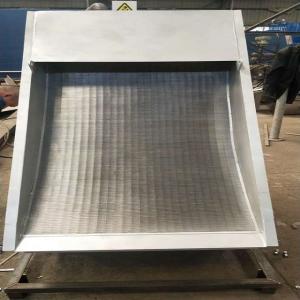

Arc vibrating screen(sieve bend) is a certain curvature radius and

angle of slotted screen. As required, it can be made of different

radii and different angles. Common angle 45 °, 60 °, 90 °, 180 ° and 270°.Mainly used for coal preparation plants, iron ore mines, food

processing and other industries.

Plastic film or wooden boxes package or as per customers' requirements.

Top Machinery is located in Chengdu, being with convenient traffic, developed communication, vast territory and a good space for development. We are professional manufacturer and exporter of accessories for water, oil, gas and environmental industries. The products mainly including filter elements like Johnson screen mesh , water well screen, V shaped wire welded screen pipe, strainer pipe, spiral screen tube, wire-wrap screen pipe, wedge wire screen tube, mine screen mesh, arc screen, flat wedge wire panel, as well as automatic washing filter, backwashing filter, drum filter, ion exchanger, etc. Since the company established, we insist on good quality, making the business range extend continually.

All of production lines are provided on a turnkey basis including

design, program, installation, commission, and complete technology

transfer and personnel training, which are backed by our extensive

experience. Complete spare parts/components and engineering

services are provided according to customers' requirements. We

sincerely hope to establish cooperation with you. We sincerely

welcome all clients to contact us for details.

Contact Details: