380*400mm Min Glass Size Glass Tempering Machine for Toughened Glass Manufacturing

Certification:ISO 9001

Minimum Order Quantity:1 set

Delivery Time:Peak Season Lead Time: 1-3 months Off Season Lead Time: within 15 workdays

Payment Terms:LC, T/T, D/P, PayPal, Western Union, Small-amount payment, Money Gram

Model NO.:ST1225

Condition:New

Contact Now

Add to Cart

Verified Supplier

Location:

Foshan Guangdong China

Address:

Changhua International Center, Boai Load, Shishan Town, Nanhai District, Foshan, Guangdong, China

Supplier`s last login times:

within 23 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

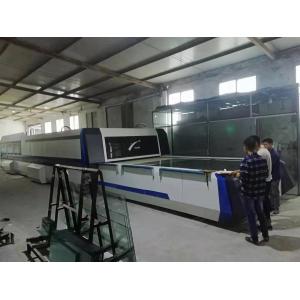

Glass tempering furnace ST1225

The furnace includes loading table, heating section , quenching and

cooling section, unloading table, and control system. It is used to

manufacture flat tempered glass for furniture, home appliance,

architecture glass, etc

| max. loading area | 1220*2500mm |

| glass thickness range | 5-19mm |

| max.glass size | 1220*2500mm |

| min.glass size | 100*300mm |

| Recommended transformer capacity | ≥315kva |

Loading Table

The loading table is composed of rubber-covered rollers and Keviar rope. When the glass is put onto the rollers, the glass will be conveyed automatically to the entrance of the turnace where it will be in ready-to-enter-turnace postion and the rollers stop moving. It will send the glass into the furnace once the computer control system gives enter command.

The loading table is composed of rubber-covered rollers and Keviar rope. When the glass is put onto the rollers, the glass will be conveyed automatically to the entrance of the turnace where it will be in ready-to-enter-turnace postion and the rollers stop moving. It will send the glass into the furnace once the computer control system gives enter command.

Heating Section

The structure of the heating section is of a double-layer box type covered with themmos-Insulation material. Inside the section there is a conveyor system with high temperature resistant ceramic rollers. Heating elements and radiation plates are installed on the upper layer and lower layer of this secion. The upper layer radiation plate is special heat resistant and ant-corrosion cast material. The heating element is of an integrated part with spiral type resistance erected on ceramio part. it's easy to replace. When the glass is going to enter the furnace, the front door of the heatna section opens the rolls of the loadino table and heatna section move at the same time.

The structure of the heating section is of a double-layer box type covered with themmos-Insulation material. Inside the section there is a conveyor system with high temperature resistant ceramic rollers. Heating elements and radiation plates are installed on the upper layer and lower layer of this secion. The upper layer radiation plate is special heat resistant and ant-corrosion cast material. The heating element is of an integrated part with spiral type resistance erected on ceramio part. it's easy to replace. When the glass is going to enter the furnace, the front door of the heatna section opens the rolls of the loadino table and heatna section move at the same time.

Flat Quenching/Gooling Section

The alloy sections and steal sheet is cold riveted to avoid deformation of heat welding, ensure effecttvely the entire flat at air face of quench. Rational nozzie aperture and arrangement of air hole guarantee the glass even coding. The upper and lower quenches are comblined with linkage and individual drives, which can actually control the rational height for air nozzle of quenches. Matched with balance control of upper and lower air amount, the top and bottom of the glasses can reach to optimum heat radiation, so as to ensure the flat of tempering glass,

The alloy sections and steal sheet is cold riveted to avoid deformation of heat welding, ensure effecttvely the entire flat at air face of quench. Rational nozzie aperture and arrangement of air hole guarantee the glass even coding. The upper and lower quenches are comblined with linkage and individual drives, which can actually control the rational height for air nozzle of quenches. Matched with balance control of upper and lower air amount, the top and bottom of the glasses can reach to optimum heat radiation, so as to ensure the flat of tempering glass,

Tinted glass

Patterned glass

Silk screen printing glass

Clear float glass

Foshan Star Glass Machinery Co.,Ltd

Foshan star Glass Machinery Co.,Ltd is a comprehensive glass

machinery company specialized in design, manufacture, selling,

after sales service and maintenance. Our products include glass straight-line edger machine, glass straight-line beveling

machine,glass drilling machine glass tempering machine etc. These machines have been widely used in various fields such as

construction, furniture, art craft, KTV and wall decoration, etc.

Having worked in this field for more than 20 years, our engineers

are qualified with rich experience and technical skills. Fssida

persists in the principle of "surviving on quality and developing on innovation".

Are you manufacture?

answer: Yes,we are the professional manufacture.

How about the service ?

answer:

1. reply it at once if from trade manager,if by email,it reply it

within 12 hours

2. deliver max. days within 15 days

3. 24 hours for after -sale serive

4. more than 12 years experience in this kind machine field

What's the guarantee ?

answer:

1. 24 hour's technical support by email or calling.

2. English manual and video tutorial.

3. Machine with 1 year quality guaranty (excluding the consumables).

4. 24 hours on line service each day, free technical support.

Do you provide equipment operation training?

answer: Yes. We can provide remotely Guided Installation.

If our price is higher than another company or factories ?

answer: please check, what is is the different of the machine parts

,service and guarantee,especially the machine inner electric parts,

sometimes, if machines have breakdown, the most reason is the

machine inner electric parts problem, but we use the famous and

reliable parts for the machines inside.

How long is the delivery time ?

answer: For standard machines, it would be 30 days; For

non-standard machines and customized machines according to clients

specific requirements, it would be 45 days.

What is the payment ?

answer: Any payment method you want,such as L/C, T/T, D/P, West-union and so on.

380*400mm Min Glass Size Glass Tempering Machine for Toughened Glass Manufacturing

Inquiry Cart

0