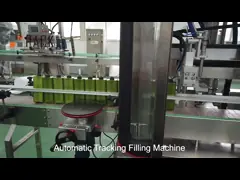

Full Automatic 2 Nozzle Daily Chemical Liquid Detergent Tracking Filling Machine

Add to Cart

Full Automatic Liquid Detergent Tracking Filling Machine

Our automatic 2-nozzle tracking-type detergent filling machine utilizes servo-driven piston measurement and tracking filling technology. This design ensures rapid filling speeds, high filling accuracy, easy maintenance and adjustments, and broad adaptability for various bottle types and materials. It is an ideal multifunctional filling solution for diverse bottle packaging in the cosmetics and daily chemical industries, including liquid detergents, a variety of cosmetics, and personal care products. Additional automated filling line equipment can be provided to meet specific capacity and production requirements.

Main Feature

1. High Production Efficiency

Equipped with servo-driven pistons and linear actuator tracking

filling nozzles, this machine ensures continuous movement for high

production efficiency. Each nozzle operates with two piston

cylinders, delivering a higher filling capacity.

2. Versatile Servo Motor Drive

Dedicated servo motors drive each piston for precise volumetric

metering, making it suitable for liquids, viscous liquids, creams,

and pastes. This setup provides stable operation and high filling

accuracy.

3. Easy Maintenance and Cleaning

The metering cylinders and nozzles feature quick-joint designs,

allowing for easy disassembly, cleaning, and maintenance. Each

piston’s speed can be independently adjusted to accommodate

different materials, providing fast and stable filling performance

that surpasses similar machines on the market.

4. Automated Features and Flexibility

With automatic counting, no-bottle-no-filling functionality,

one-button washing, and formula-saving capabilities, the machine

can automatically adjust settings based on stored bottle formula

data. This allows for quick and convenient production changes,

making it ideal for handling various bottle shapes and sizes with

efficiency and cost-effectiveness.

5. User-Friendly Design

Features include a PLC and touch screen control, one-button

washing, formula saving, and speed inverter control, making the

machine easy to operate and maintain.

6. Modular Integration Options

Can be integrated with automatic capping, sealing, labeling, and

packaging machines based on production needs and layout

requirements.

Product Parameters

How Tracking Filling Machine Works:

Bottle tracking filling machine utilizes multiple servo motors to control the up-and-down movement of the capping head. During the capping process, the bottles move continuously, while the PLC manages the entire operation to ensure that neither the bottles nor caps are damaged. This setup enhances production speed and stability, delivering efficient and reliable performance.

Product Details

After-Sale Service for Tracking Filling Machines

1. Installation Services

Our skilled technicians are available worldwide to install your tracking filling machine. This service includes a comprehensive fee covering installation,

travel, meals, and related expenses.

2. Comprehensive Training

We provide hands-on training either on-site or at our facility,

customized for dealers, operators, engineers, and technicians to

ensure your machine operates at peak performance.

3. Warranty and Guarantee

Each tracking filling machine comes with a one-year quality

assurance period. During this period, we offer fast repair

services, replacement parts, and effective troubleshooting to

minimize any downtime.

4. Consultation Services

Benefit from our free consultation service, where our expert sales

team will recommend tailored solutions to meet your needs. We also

offer detailed CAD drawings of labeling machine designs to support

your decision-making.

5. 24/7 Technical Support

Our team provides long-term, 24/7 technical support via email or

phone, ensuring you receive timely and efficient assistance

whenever you need it.

6. Spare Parts Supply

Each machine shipment includes a set of essential spare parts at no

additional cost. Additionally, you can order a full range of

high-quality spare parts from us whenever necessary.