Beer Bottle Automatic Capping Machine With Cap Feeder Dual Capping Heads Tracking

Add to Cart

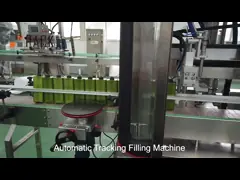

Fully Automatic Dual Capping Heads Tracking Capping Machine With Cap Feeder High Speed

Npack Built high efficient Bottle Tracking Capper

Introducing the Npack Np-TC-2 series automated tracking capping

machine, a revolutionary modification of the conventional inline

pick and place capping machine. This cutting-edge technology is

meticulously designed to overcome the low capacity constraints

often associated with traditional counterparts. At the heart of its

operation is a state-of-the-art Motion Controller, elevating

efficiency and precision to new heights when compared to the

standard Programmable Logic Controller (PLC) systems.

During the capping process, the machine's capping heads move in perfect synchronization with the bottles, ensuring a seamless operation. The Np-TC-2 series can be tailored with either one or two capping heads, delivering an impressive capacity ranging from 40 to 80 bottles per minute (b/m). Notably, this capacity remains consistent across various bottle and cap sizes, accommodating volumes from 50ml to 5000ml.

One of the standout features of this machine is its continuous bottle operation capability. This innovation ensures that even when bottles are nearing full capacity post-filling, the risk of liquid splashing out during capping is minimized. The Np-TC-2 series integrates a highly efficient servo system, comprising belt servo, horizontal moving servo, up and down moving servo, and a servo capping head system.

The servo motor plays a pivotal role in automating the gripping and capping processes, guaranteeing not only precise movements but also swift and high-speed operations. With the Npack Np-TC-2 series, experience a transformative approach to capping, where efficiency, accuracy, and adaptability converge to redefine the standards in automated tracking capping technology.

Main Features

- The precision of capping is masterfully controlled by the servo system paired with a torque module, granting the flexibility to freely adjust cap tightness to meet specific requirements.

- Crafted for durability and hygiene, the entire machine is constructed from 304 stainless steel material, ensuring resilience and adherence to stringent quality standards.

- Tailoring to diverse cap types, the cap feeding system incorporates adaptability through the use of either a Cap elevator or vibrator, catering to the specific needs of the application.

- Achieving versatility without the need for parts replacement, the machine simplifies adjustments for different bottle and cap sizes, excluding the capping head, streamlining the operational process.

- An innovative feature prevents liquid spillage during capping, eliminating the necessity for bottle stoppage. The dynamic movement of the capping heads with the bottles ensures a smooth and continuous capping process.

- Experience unparalleled flexibility with the capability for rapid switching between various caps and bottles, making the machine highly adaptable to a wide range of production needs.

- The cap loading system boasts a high success rate, employing a pick & place capping mechanism that ensures precise and reliable cap placement.

- Delivering flawless capping results, the machine is engineered to achieve perfection without causing any damage to the bottles or caps, maintaining the integrity of the packaging throughout the process.

Product Detials

Parameter

| No. | Model | NP-TC-2 | |

| 1 | Speed | 80pcs/Min base on double capping heads | |

| 2 | Cap Type | Screw cap,snap caps | |

| 3 | Bottle Diameter | 30-120mm customized | |

| 4 | Bottle Height | 50-380mm | |

| 5 | Cap Diameter | 18-120mm | |

| 5 | Power | 5.5KW for two heads capping | |

| 6 | Air Pressure | 0.6-1Mpa | |

| 7 | Voltage | 380V, 50Hz/60Hz | |

| 8 | Weight | 1000KG | |

| 9 | Dimension | 2200mm*1400mm * 2250mm | |

Main Components List

No. | Item | QTY | UNIT | BRAND | REMARK |

1 | Servo Motor | 4 | SET | HCFA | China |

2 | Convertor | 6 | PCS | HCFA | china |

3 | Touch Screen | 1 | PCS | HCFA | China |

4 | Relay | 2-3 | PCS | Siemens | Germany |

5 | Sensor | 3 | PCS | SICK | Germany |

6 | Optical | 1 | PCS | KEYENCE | JAPAN |

7 | Air switch | 1 | PCS | Schneider | FRANCE |

8 | Solenoid Valve | 1-2 | PCS | AIRTAC | TAIWAN |