Add to Cart

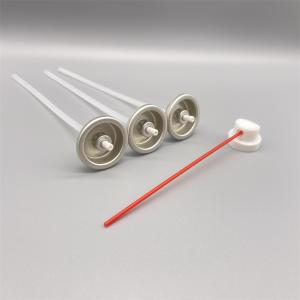

Subsea MDF Kit Valve Activator for Offshore Oil and Gas Production with Pressure-Compensated Design

Product Description:

The Subsea MDF Kit Valve Activator is a feat of marine engineering,

designed to perform critical valve functions in the deep-sea

environment. Deployed on subsea production trees, manifolds, and

pipelines, this robust actuator must withstand immense hydrostatic

pressure, corrosive seawater, and total isolation for extended

periods. Its key feature is a pressure-compensated design, which

equalizes the internal pressure with the external ocean pressure,

preventing the housing from being crushed and ensuring the internal

mechanics can operate smoothly at any depth. Constructed from

high-strength, corrosion-resistant alloys like Duplex or Super

Duplex stainless steel, it offers exceptional resistance to both

seawater and sour gas (H2S). The actuator is filled with a

specialized dielectric fluid that provides lubrication and

corrosion protection while acting as the compensating medium. Every

component is tested to the highest standards to guarantee absolute

reliability, as retrieval for repair is phenomenally expensive. The

MDF Kit Valve Activator is the workhorse of the subsea industry,

enabling the remote control of wells, the management of production

flows, and the execution of emergency shutdowns on the ocean floor,

making deep-water oil and gas extraction possible and safe.

Bullet Points:

Built for the extreme pressures of offshore oil and gas production.

Pressure-compensated design ensures functionality at great depths.

Constructed from corrosion-resistant marine-grade alloys (Duplex Stainless Steel).

Provides reliable valve control for subsea Christmas trees and manifolds.

Equipped with ROV (Remotely Operated Vehicle) interfaces for backup operation.

Specific Application Scenario

This activator is mounted on a subsea Christmas tree one mile below

the ocean surface, controlling the main production wing valve that

regulates the flow of oil and gas from the wellbore to the

pipeline.

Factory Production Floor

Production involves ultra-precise machining and welding in a

certified facility. Every housing is subjected to hydrostatic

pressure tests far exceeding its rated depth. The final assembly

and fluid filling occur in a clean room, and each unit undergoes a

full-function test in a hyperbaric chamber.

Packing and Transportation

The activator is coated in a temporary protective coating, and all

ports are sealed with multiple layers of protective caps. It is

then bolted to a custom shipping skid and crated for secure

transport to the dock for load-out to an offshore vessel.

FAQ

1. What is the maximum depth rating for this subsea actuator?

Our standard subsea actuator models are rated for water depths up to 3,000 meters (10,000

feet), with custom designs available for even greater depths.

2. How does the pressure-compensated design work?

The pressure-compensated design uses a flexible membrane or bladder system that allows the

internal dielectric fluid to equalize with the external sea

pressure, nullifying the crushing force on the housing.

3. Why are marine-grade alloys like Duplex Stainless Steel used?

Marine-grade alloys provide the necessary yield strength to withstand high pressure

while offering superior resistance to pitting and stress corrosion

cracking in chloride-rich seawater, which is critical for offshore oil and gas production.

4. What are the primary and secondary control methods?

Primary control is typically via an umbilical from the surface.

Secondary control is through an ROV interface, allowing a

submersible to manually operate the valve if the primary system

fails.

5. What is the expected service life in a subsea environment?

These actuators are designed for a service life of 25+ years with

minimal maintenance, reflecting the immense cost and difficulty of

subsea intervention.