Add to Cart

Smart Connected WD-40 Lubricant Valve with RFID Tag for Automated Inventory and Usage Analytics.

Product Description:

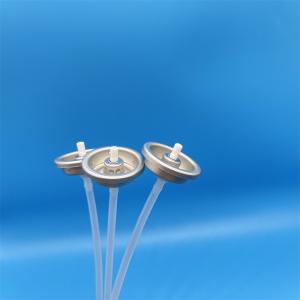

Step into the future of industrial supply chain management with our

Smart Connected Valve. Each valve is embedded with a unique,

passive RFID (Radio-Frequency Identification) tag, turning every

can of lubricant into a trackable asset. This allows for automated

inventory management through fixed readers in storage rooms or

mobile readers during audits, providing real-time data on stock

levels and consumption patterns. The valve itself provides a

reliable, consistent spray for all lubrication tasks, but its true

value lies in the data it provides. Facility managers can monitor

usage across departments, predict restocking needs with precision,

and prevent theft or misallocation of supplies. This valve is the

cornerstone of a digital, data-driven maintenance strategy,

eliminating manual stock-taking and bringing unparalleled

visibility to your consumable usage. Integrate it with your asset

management software for a seamless, smart factory ecosystem.

Bullet Points:

Integrated passive RFID tag for unique identification and tracking of each canister.

Enables fully automated inventory management and restocking alerts.

Provides valuable data analytics on lubricant consumption and usage patterns.

Prevents loss and improves accountability for supply chain management.

Delivers the same reliable seal and spray pattern for a perfect protective coating.

Specific Application Scenario: A large manufacturing plant has RFID readers on the tool crib. As a technician checks out a can, it is automatically scanned, deducting it from inventory and charging the cost to their department.

Factory Production Floor: Valves are manufactured on a standard line, with the RFID inlay being applied and sealed within the valve housing during a final assembly step in an ESD-safe environment.

Packing and Transportation: Packaged in boxes that are also tagged with a master RFID for bulk tracking. Shipped with documentation about the tag specifications for IT integration.

FAQ:

Q: What type of RFID tag is used, and what is its read range?

A: It uses a UHF passive RFID tag with a typical read range of 3-5

meters with a standard fixed reader, ideal for portal and

shelf-based scanning.

Q: Does the RFID tag require a battery?

A: No, it is a passive tag that is powered by the radio wave energy

from the reader, making it maintenance-free for the life of the

valve.

Q: Can we integrate this data with our existing ERP system?

A: Yes, the unique ID from each tag can be easily linked to your

enterprise resource planning (ERP) or computerized maintenance

management system (CMMS) software.

Q: Is the tag resistant to the chemicals in lubricants and

penetrants?

A: Yes, the tag is fully encapsulated and sealed within the valve's

polymer housing, protecting it from chemical exposure and physical

impact.

Q: What happens to the tag when the can is empty?

A: The valve (with the tag) can be unscrewed and transferred to a

new canister, or the tag can be decommissioned in your system upon

disposal.