Product Details

End-suction close-coupled single-stage pump

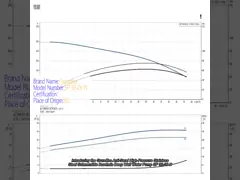

NBG 150-125-500/548 AIAF2AESBQQEYW3

Number: 93351091

Applications:

- Commercial heating

- Commercial air conditioning

- Commercial water pressure boosting

- District heating

- Industrial cleaning processes

- Heating supply

- Desalination

- Municipal water transmission and distribution

- Irrigation

- Community and building water supply

Short-coupled pump compliant with ISO 2858

NBG 150-125-500/548 AIAF2AESBQQEYW3

The non-self-priming single-stage volute centrifugal pump is

designed in accordance with ISO 5199, and its dimensions and rated

performance comply with ISO 2858 (16 bar). The flanges are of PN 16

type, with dimensions conforming to EN 1092-2. The pump is equipped

with an axial suction port, a radial discharge port, a horizontal

shaft, and a back-pull-out design, allowing maintenance personnel

to disassemble the motor, motor bracket, cover, and impeller

without loosening the pump casing or pipelines. The unbalanced

O-type shaft seal meets the requirements of DIN EN 12756. An

air-cooled asynchronous motor is closely coupled to the pump.

| |

Controller:

- Frequency converter: None

- Pressure sensor: N

Liquid:

- Liquid conveyed: Water

- Liquid temperature range: -25 .. 120 °C

- Liquid temperature during operation: 20 °C

- Density: 998.2 kg/m³

Technical Data:

- Pump speed basis: 1,490 rpm

- Rated flow rate: 342.8 m³/h

- Rated head: 95.56 m

- Impeller actual diameter: 548 mm

- Impeller nominal speed: 500

- Impeller type: Standard

- Shaft seal configuration: Single

- Main shaft seal: BQQE

- Shaft seal code: BQQE

- Curve tolerance: ISO9906:2012 3B

- Bearing design: Standard

Materials:

- Pump housing: Cast iron

- Pump housing: EN-GJL-250

- Pump housing: ASTM class 35

- Wear ring: Brass

- Wear ring material: CuZn34Mn3AI2Fe1-C

- Impeller: Cast iron

- Impeller material: EN-GJL-200

- Impeller material: ASTM class 30

- Internal pump housing coating: CED

- Shaft: Stainless steel

- Shaft material: EN 1.4301

- Shaft material: AISI 304

Installation:

- Maximum ambient temperature: 40 °C

- Maximum operating pressure: 16 bar

- Pipeline connection standard: EN 1092-2

- Inlet size: DN 150

- Outlet size: DN 125

- Pressure rating for pipe connection: PN 16

- Bearing lubrication: Grease

- Pump casing with support feet: Yes

- Yes = With support block, No = Without support block: N

Electrical Data:

- Motor model: 315LA

- Rated power - P2: 160 kW

- Power supply frequency: 50 Hz

- Rated voltage: 3 x 380-400/660-690 V

- Rated current: 283-269/163-156 A

- Starting current: 770 %

- Cos phi - Power factor: 0.89

- Rated speed: 1,490 rpm

- Efficiency: IE4 96.6%

- IE efficiency class: IE4

- Motor full-load efficiency: 96.6 %

- Motor efficiency at 3/4 load: 96.4 %

- Motor efficiency at 1/2 load: 95.5 %

- Motor pole count: 4

- Enclosure rating (IEC 34-5): 55 (Protect. water jets/dust)

- Insulation class (IEC 85): F

- Motor number: 92555138

- Bearing insulation type N end: COATED RING

Other:

- Minimum Efficiency Index, MEI ≥: 0.50

- Net weight: 1,590 kg

- Gross weight: 1,730 kg

- Transport volume: 2.35 m³

Company Profile

. Located in Tianjin, China, Tianjin Shiny-Metals Technologyco.,

Ltd. is a professional company that specializes in the research and

development, design, production, sales, trade, and service of

pumps. Our products are exported to more than 40 countries and

regions, continuously building our global brand reputation. We

offer a wide range of pumps, including centrifugal pumps, axial

flow pumps, jet pumps, submersible pumps, deep-well submersible

pumps, and swimming pool pumps, with over 500 specifications

available. Our company has obtained the ISO 9001 certification from

the International Organization for Standardization (CQC). In

addition, our civilian motors have undergone product evaluation for

CCC China mandatory certification. We have also received

certifications such as CE, EMC, GS, RoHS, EAC, SASO, and ST. Our

company is dedicated to meeting customer needs with high-quality

products, reasonable prices, and exceptional pre-sales, in-sales,

and after-sales services. We adhere to the management principles of

"quality first, customer first, and reputation-based" and are

committed to providing global customers with the best solutions for

water pumps and water treatment systems, improving their quality of

life. Our goal is to make the world a better place through water,

and we strive to make water even better.