Product Details

Product Overview

- The DFMSD series split - case multistage centrifugal pumps are

developed by our company. They incorporate advanced technologies of

similar foreign products and combine with our company's years of

design experience. These are horizontal multistage centrifugal

pumps with axial split - case type and supported at both - end

centerlines. They feature an advanced and reasonable structure, a

wide high - efficiency range, high efficiency, good cavitation

performance, low vibration, stable and reliable operation, and long

service life.

- The DFMSD medium - and low - pressure pumps comply with the GB/T

5657 Technical Conditions for Centrifugal Pumps (III) standard.

- The DFMSD medium - high - pressure pumps, high - temperature pumps,

abrasion - and corrosion - resistant pumps, and seawater pumps

comply with the GB/T 5656 Technical Conditions for Centrifugal Pumps (II) standard; they can also meet the GB/T 16907 standard and API 610

standard according to customer needs.

Application Fields

- Municipal/industrial water supply or water diversion projects

- Mine drainage

- Descaling

- Reverse osmosis water supply

- Water injection on offshore platforms

- Water supply for coal chemical washing towers

- Coal mining by hydraulic methods

- Feedwater for medium - and medium - high - pressure boilers

- Pipeline crude oil transportation

- Petroleum and chemical processes

Operating Conditions

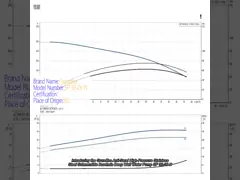

- Flow rate: ≤ 3500 m³/h.

- Working pressure: ≤ 15 MPa [1].

- Medium temperature: -20°C to +160°C [2].

- Operating speed: 1480 r/min, 2960 r/min.

- Driving modes: Motor - driven, turbine - driven, engine - driven,

as well as variable - frequency, hydraulic coupling, and gearbox -

driven.

- Direction of rotation: When viewed from the drive end, the pump

rotates counterclockwise; it can also be designed according to user

requirements.

- Inlet and outlet mode: Side - inlet and side - outlet.

- Impeller type: Closed.

- Shaft seal type: Mechanical seal or packing seal.

- Flange standard: GB/T 9124.1 Steel Pipe Flanges Part 1: PN Series is the standard flange, and other standards can also be

implemented.

Note:

[1] For DFMSD medium - and low - pressure pumps and high -

temperature pumps, the suction port pressure + maximum pump

pressure ≤ 7 MPa.

For DFMSD medium - high - pressure pumps, abrasion - and corrosion

- resistant pumps, and seawater pumps, the suction port pressure +

maximum pump pressure ≤ 15 MPa.

[2] For DFMSD medium - and low - pressure pumps, the temperature ≤

105°C; when the medium temperature ≥ 80°C, external cooling water

must be connected for cooling.

For DFMSD high - temperature pumps, the temperature ≤ 160°C.

External cooling water must be connected for cooling, and

mechanical seal cooling flushing should be adopted.

Product Structural Features

- Impeller and Shaft Balance: Balanced according to ISO 1940 - 1 G2.5 grade, achieving smooth

rotation with no vibration.

- Heavy - Duty Bearings: Can be equipped with self - aligning radial spherical bearings

and axial thrust bearings. The heavy - duty radial spherical

bearings can compensate for radial movement, and the thrust

bearings can withstand axial force.

- Bearing Isolator: Prevents external contaminants from entering, significantly

reducing the risk of bearing damage.

- Flange Connection: Meets GB/T 9124.1 standard for PN series flanges for suction and

discharge. Other standard flanges can also be used.

- Single - Stage Cover Bolt Structure: The bolt layout is designed to minimize bending stress. High -

strength bolts with fine - pitch threads are used. The pump cover

and end cover can be easily removed.

- Equal - Load Design of Diaphragm Gasket: Balances radial force, reduces vibration, and lowers pump noise.

- Transition Flow Passage: Optimizes flow, minimizing friction loss and maximizing

efficiency.

- Split - Middle Throttle Bush: Can withstand large axial and radial forces, simplifying rotor

assembly and disassembly.

- Impeller Back - Pressure Device: Ensures balanced axial force. Different impeller vane numbers can

balance radial force, reducing axial movement.

- Integrated Pressure - Equalizing Pipe: The balanced pressure - equalizing pipe makes the packing seal

only bear inlet pressure.

- Sealing Gland: Meets GB/T 14624.9 standard for gland studs and nuts, ensuring

reliable connection and easy disassembly and assembly.

Company Profile

. Located in Tianjin, China, Tianjin Shiny-Metals Technologyco.,

Ltd. is a professional company that specializes in the research and

development, design, production, sales, trade, and service of

pumps. Our products are exported to more than 40 countries and

regions, continuously building our global brand reputation. We

offer a wide range of pumps, including centrifugal pumps, axial

flow pumps, jet pumps, submersible pumps, deep-well submersible

pumps, and swimming pool pumps, with over 500 specifications

available. Our company has obtained the ISO 9001 certification from

the International Organization for Standardization (CQC). In

addition, our civilian motors have undergone product evaluation for

CCC China mandatory certification. We have also received

certifications such as CE, EMC, GS, RoHS, EAC, SASO, and ST. Our

company is dedicated to meeting customer needs with high-quality

products, reasonable prices, and exceptional pre-sales, in-sales,

and after-sales services. We adhere to the management principles of

"quality first, customer first, and reputation-based" and are

committed to providing global customers with the best solutions for

water pumps and water treatment systems, improving their quality of

life. Our goal is to make the world a better place through water,

and we strive to make water even better.