Product Details

Multistage In-line Pump

CRI

Applications:

Vertical multistage centrifugal pump with the suction inlet and the

discharge outlet at the same horizontal level. The material of the

pump body in contact with the liquid is stainless steel (EN 1.4301)."

CRI Vertical Multistage Centrifugal Pump: High Flexibility and

Multiple Application Scenarios

The CRI pump of Grundfos is a vertical multistage centrifugal pump,

which has the ability to provide various flow rates and different

pressure levels. Made of AISI 304-grade stainless steel, it is

suitable for transporting water and other non-corrosive liquids.

The CRI vertical multistage centrifugal pump can also be applied in

multiple scenarios, such as liquid transportation, ethylene glycol

transportation, circulation systems, boosting of cold and hot

water, and transportation of slightly corrosive liquids. Thanks to

the flexibility and adaptability of the CRI pump, it has become an

ideal choice for various liquid transortation systems

Excellent Corrosion ResistanceAll liquid - contacting components of CRI vertical multistage

centrifugal pumps are made of AISI 304 stainless steel. This

effectively protects the liquid - contacting parts from corrosion

and oxidation. Besides being corrosion - resistant, it also

features wear - resistance, high strength, and heat - resistance.

It can maintain good performance in various environments, making

the CRI pump more efficient and reliable in use. Even under harsh

site conditions, it can still deliver outstanding performance.

| |

High Hydraulic Efficiency

Through extensive simulation - driven design and verification, the

insights in fluid dynamics optimize the product performance.

High Motor Utilization Rate

The CRI vertical multistage centrifugal pump series optimizes the

maximum utilization rate of the motor's power output.

Multifunctional Solutions

The special water pump for deep - well pumping is suitable for

small - scale water supply systems, with a maximum pumping depth of

up to 90 meters.

CRI 20 - 17 A - FGJ - A - E - HQQE

Vertical multistage centrifugal pump with the inlet and outlet on

the same horizontal plane (inline). The material of the pump body

in contact with the liquid is stainless steel. The cartridge shaft

seal improves the reliability of the machine and the safety of

operation, and simplifies maintenance. Electrical energy is

transmitted through a split - type coupling. Pipe connections are

made via a combined DIN - ANSI - JIS flange. An asynchronous motor

with three phases, a cooling fan and feet is installed on the pump.

Liquid

- Transported liquid: Water

- Liquid temperature range: -20..120 °C

- Liquid temperature during operation: 60 °C

- Density: 983.2 kg/m³

Technology

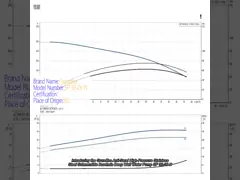

- Pump speed on which pump data is based: 2934 revolutions per minute

- Rated flow rate: 21 m³/h

- Rated head: 202.9 meters

- Pump orientation: Vertical

- Shaft seal configuration: Single

- Main shaft seal: HQQE

- Shaft seal code: HQQE

- Approvals: CE, EAC, UKCA, SEPRO

- Approvals for drinking water: WRAS, ACS

- Curve tolerance: ISO9906:2012 3B

Materials

- Base: Stainless steel

- Impeller: Stainless steel

- Bearing: SIC

Installation

- Maximum ambient temperature: 60 °C

- Maximum operating pressure: 25 bar

- Maximum pressure at specified temperature: 25 bar / 120 °C; 25 bar

/ -20 °C

- Interface type: DIN / ANSI / JIS

- Inlet size: DN 50

- Suction port size: 2 inch

- Outlet size: DN 50; 2 inch

- Pressure rating for pipe connection: PN 25

- Flange rating inlet: 300 lb

- Flange size for motor: FF300

Electrical Data

- Motor standard: IEC

- Motor model: 160LB

- Rated power-P2: 18.5 kW

- Power required by the pump (P2): 18.5 kW

- Power supply frequency: 50 Hz

- Rated voltage: 3 x 380 - 415D/660 - 690Y V

- Rated current: 34.5 - 32.5/20.0 - 18.8 A

- Starting current: 830 - 980 %

- Cos phi-Power factor: 0.89 - 0.85

- Rated speed: 2940 - 2950 revolutions per minute

- IE efficiency class: IE3

- Motor full - load efficiency: 92.4 %

- Motor efficiency at 3/4 load: 93.2 - 93.0 %

- Motor efficiency at 1/2 load: 93.2 - 92.2 %

- Number of motor poles: 2

- Encapsulation class (IEC 34 - 5): 55 Dust/Jetting

- Insulation class (IEC 85): F

- Motor number: 85U16528

Controller

- Frequency converter: None

Others

- Terminal box position: 6

- Minimum efficiency index, MEI ≥: 0.70

- Net weight: 183 kg

- Gross weight: 223 kg

- Transport volume: 0.805 m³

- Custom tariff no.: 84137099.90

Company Profile

. Located in Tianjin, China, Tianjin Shiny-Metals Technologyco.,

Ltd. is a professional company that specializes in the research and

development, design, production, sales, trade, and service of

pumps. Our products are exported to more than 40 countries and

regions, continuously building our global brand reputation. We

offer a wide range of pumps, including centrifugal pumps, axial

flow pumps, jet pumps, submersible pumps, deep-well submersible

pumps, and swimming pool pumps, with over 500 specifications

available. Our company has obtained the ISO 9001 certification from

the International Organization for Standardization (CQC). In

addition, our civilian motors have undergone product evaluation for

CCC China mandatory certification. We have also received

certifications such as CE, EMC, GS, RoHS, EAC, SASO, and ST. Our

company is dedicated to meeting customer needs with high-quality

products, reasonable prices, and exceptional pre-sales, in-sales,

and after-sales services. We adhere to the management principles of

"quality first, customer first, and reputation-based" and are

committed to providing global customers with the best solutions for

water pumps and water treatment systems, improving their quality of

life. Our goal is to make the world a better place through water,

and we strive to make water even better.