Product Details

CR 5-36 A-FGJ-A-E-HQQE

Vertical multistage centrifugal pump with inlet and outlet on the

same horizontal plane (in-line). The pump head and base are made of

cast iron, while all other liquid-contact components are

manufactured from stainless steel. The cartridge-type shaft seal

enhances the machine's reliability and operational safety, making

maintenance more straightforward. Electrical energy is transmitted

via a split coupling. Pipe connections are achieved through

DIN-ANSI-JIS union flanges. The pump is equipped with a three-phase

asynchronous motor featuring a cooling fan and a foot bracket.

CR 5-36 A-FGJ-A-E-HQQE

Number: 98675229

Applications:

- Commercial heating

- Commercial air conditioning

- Commercial water pressure boosting

- District heating

- District cooling

- Machining

- Industrial cleaning processes

- Process water distribution

- Heating supply

- Refrigeration

- Industrial water supply and transportation

- Industrial wastewater

- Process water treatment

- Desalination

- Surface water intake

- Drinking water treatment

- Municipal water transmission and distribution

- Irrigation

- Solar water solutions

- Community and building water supply

Vertical multistage centrifugal pump

| |

Liquid:

- Liquid conveyed: Water

- Liquid temperature range: -20 .. 120 °C

- Liquid temperature during operation: 20 °C

- Density: 998.2 kg/m³

Technical Data:

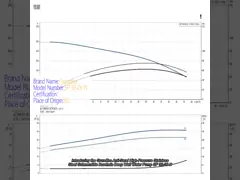

- Pump speed basis: 2919 rpm

- Rated flow rate: 5.8 m³/h

- Rated head: 189.2 m

- Pump orientation: Vertical

- Shaft seal configuration: Single

- Main shaft seal: HQQE

- Shaft seal code: HQQE

- Approvals: CE, EAC, UKCA, SEPRO

- Drinking water certifications: WRAS, ACS

- Curve tolerance: ISO9906:2012 3B

Materials:

- Base: Cast iron

- Base standards: EN 1561 EN-GJL-200 / ASTM A48-25B

- Impeller: Stainless steel

- Impeller material: EN 1.4301 / AISI 304

- Bearings: SIC

Installation:

- Maximum ambient temperature: 60 °C

- Maximum operating pressure: 25 bar

- Maximum pressure at specified temperatures:

- 25 bar / 120 °C

- 25 bar / -20 °C

- Connection types: DIN / ANSI / JIS

- Inlet size: DN 25/32 / 1 1/4 inch

- Suction port size: 1 1/4 inch

- Outlet size: DN 25/32 / 1 1/4 inch

- Pressure rating for pipe connection: PN 25

- Flange inlet rating: 250 lb

- Motor flange size: FF265

Electrical Data:

- Motor standard: IEC

- Motor model: 132SC

- Rated power - P2: 5.5 kW

- Pump required power (P2): 5.5 kW

- Power supply frequency: 50 Hz

- Rated voltage: 3 x 380-415D V

- Rated current: 11 A

- Starting current: 1080-1180 %

- Cos phi - Power factor: 0.87-0.82

- Rated speed: 2920-2940 rpm

- IE efficiency class: IE3

- Motor full-load efficiency: 89.2 %

- Motor efficiency at 3/4 load: 90-89.8 %

- Motor efficiency at 1/2 load: 89.6-88.4 %

- Motor pole count: 2

- Enclosure rating (IEC 34-5): 55 Dust/Jetting

- Insulation class (IEC 85): F

- Motor number: 85U18417

Controller:

- Frequency converter: None

Other:

- Junction box position: 6

- Minimum Efficiency Index, MEI ≥: 0.57

- Net weight: 84.8 kg

- Gross weight: 110 kg

- Transport volume: 0.429 m³

Company Profile

. Located in Tianjin, China, Tianjin Shiny-Metals Technologyco.,

Ltd. is a professional company that specializes in the research and

development, design, production, sales, trade, and service of

pumps. Our products are exported to more than 40 countries and

regions, continuously building our global brand reputation. We

offer a wide range of pumps, including centrifugal pumps, axial

flow pumps, jet pumps, submersible pumps, deep-well submersible

pumps, and swimming pool pumps, with over 500 specifications

available. Our company has obtained the ISO 9001 certification from

the International Organization for Standardization (CQC). In

addition, our civilian motors have undergone product evaluation for

CCC China mandatory certification. We have also received

certifications such as CE, EMC, GS, RoHS, EAC, SASO, and ST. Our

company is dedicated to meeting customer needs with high-quality

products, reasonable prices, and exceptional pre-sales, in-sales,

and after-sales services. We adhere to the management principles of

"quality first, customer first, and reputation-based" and are

committed to providing global customers with the best solutions for

water pumps and water treatment systems, improving their quality of

life. Our goal is to make the world a better place through water,

and we strive to make water even better.