380V Horizontal Structure Vacuum Sublimation Furnace For Silicon Oxide Production

Add to Cart

1. Suitable for mass production of vapor deposition materials such as silicon oxide;

2. High precision temperature difference control, high temperature vacuum furnace;

3. With high vacuum sublimation, reaction, degreasing, dehydration, vapor deposition material automatic grinding scraping, furnace collection and other special process capabilities.

Products Features:

1.A large amount of material, high production efficiency.

2.The whole process is completely closed and automatic operation to avoid dust flying, and the production site environment is clean and tidy.

3.The temperature is controlled within 1500 degrees, and the heating rate is fast. Can maintain stable operation under vacuum.

Main Technical Parameter :

| Model | JT-SHL-118 | JT-SHL-226 | JT-SHL-385 | JT-SHL-804 |

| Furnace Structure | Horizontal | |||

| Constant Temperature Zone Size | Φ500mm*600mm | Φ600mm*800mm | Φ700mm*1000mm | Φ800mm*1600mm |

| Furnace Body | The inner and outer double-layer water cooling structure, and the contact part of the cooling water made of 304 stainless steel, effectively prevent the furnace body for a long time to use gas leakage phenomenon | |||

| Sublimation System | The heating zone is composed of induction coil, heavy corundum, graphite hard felt and isostatic graphite. The collection area is composed of 310S stainless steel and insulation layer. | |||

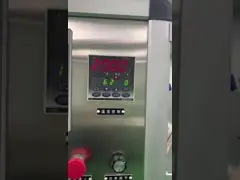

| Temperature Control System | Using PLC touch screen centralized control mode, automatic control, with network port, can realize remote control. | |||

| Heating System | It is composed of multistage vacuum pump, vacuum valve, pressure controller and pipeline. | |||

| Vacuum System | It is composed of multistage vacuum pump, vacuum valve, pressure controller and pipeline. | |||

| Cooling System | Equipped with closed cooling system, internal circulation with deionized water, will not cause scaling equipment pipeline, internal circulation water loss is small, external circulation with tap water, automatic water refill, fan start heat dissipation; Good heat dissipation effect, integrated environmental protection, small footprint and so on. | |||

The equipment is composed of sublimation system, collection system, heating system, temperature control system, vacuum system, mechanical system and cooling system. | ||||