Add to Cart

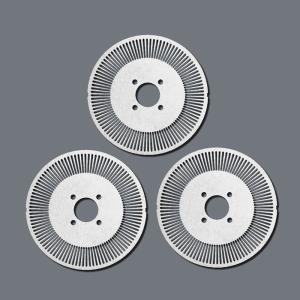

Metal Chemical Etching Optical Encoder Disc Service

| Xinhaisen provides metal chemical etching solutions for producing stainless steel encoder disc, delivering faster turnaround, greater design flexibility, and more cost-efficient results compared to conventional perforation methods. |

Nowadays, the optical encoders applicate in many industries, for examples:

Industrial Automation – Position and speed feedback for motors, conveyors, and robotic arms.

CNC Machines – Accurate control of cutting, milling, and drilling operations.

Robotics – Motion control and joint position tracking in robotic systems.

Elevators & Lifts – Monitoring and controlling platform position and movement speed.

Printing & Packaging Equipment – Precise registration and alignment during high-speed operations.

Aerospace & Defense – Navigation systems, turret positioning, and antenna tracking.

Medical Devices – Imaging systems, surgical robots, and automated lab equipment.

Renewable Energy – Yaw and pitch control in wind turbines.

Semiconductor Manufacturing – Positioning wafers and inspection stages with micron-level accuracy.

Automotive – Steering angle sensing, throttle control, and automated driver assistance systems (ADAS).

Specifications of Metal Chemical Etching Optical Encoder Discs:

| Material Capabilities | Metal like Stainless Steel, Copper etc. |

| Thickness | 0.03 mm to 1 mm |

| Product Dimension | 600*600 mm or Customized |

| Smallest open hole | D= 0.1mm when Thickness range from 0.03mm to 0.05mm |

| Centre to Centre for holes | 1.5*Thickness |

| Product precision | ± 0.01mm (common difference). It’s generally 20% of material thickness |

| Surface treatment for choice | Silver, Gold, Tin Plated, Matt Finish, Paint |

Want to custom metal optical encoder disc by metal chemical etching?

| Photochemical machining is a high-precision subtractive process that removes material from metal sheets through controlled chemical reactions. By utilizing cost-efficient digital tooling and producing all mesh openings in a single step, it enables the fabrication of components with nearly limitless complexity, structures, and geometries. This technique reduces both costs and lead times while allowing rapid, hassle-free design modifications. |

Benifits of Etched Metal Filter Screens

| Unlimited Complex | Smallest Opening to 0.02mm | Burr-Free & Stress-Free | Prototype to High Volume Production |

How to Custom Metal Optical Encoder Disc from Xinhaisen?

1. Send Your Design Provide your drawing file (DXF, DWG, STP, PDF) with dimensions, material type, and thickness.

2. Get a Quote We’ll evaluate your design and send you a quotation based on quantity, material, and complexity.

3. Confirm & Start Production Once the order is confirmed, we’ll prepare phototools and begin the etching process.

4. Quality Inspection All parts go through strict quality checks to ensure accuracy and consistency.

5. Packaging & Delivery Your parts will be carefully packaged and shipped to your address on time.

Ready to discuss your Metal Optical Encoder Disc design?