Product Details

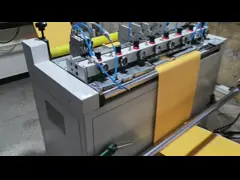

Automatic HEPA Filter Pleating Production Line And Many Kinds Of

Equipment

Product Paramenters

| Machine Name | Automatic HEPA Filter Pleating Production Line And Many Kinds Of

Equipment |

| Material | HEPA |

| type | Filter |

| application | Car, RV, Outdoor, Hotel, garage, Commercial, Household |

| place of origin | China,Bengbu |

| Brand Name | Bengnu Tongchen |

| Material | Paper and non-woven |

| Package | Opp bag / Carton box |

| Application | Product air filter |

| Usage | Car air filter,carbon fliter,oil fliter |

| Customization | Accepted |

Product Functions and Features of Automatic HEPA Filter Pleating

Production Line And Many Kinds Of Equipment:

- Servo System High Speed Rotary Pleat Machine

- Deep Pleat Can Reach 300mm Folding Height Automatic

- Adjustable Height Range 20-300mm

- Gluing Use Foaming System

- Full-auto Fiber Glass Pleating Machine

- Motor configuration: full digital servo motor and drive, brand:

INOVANCE unit: 5 sets 2 High precision reducer, brand: Newshidat

- 2 Touch screen configuration: 10 inch touch screen, brand: INOVANCE

Our Advantages

Details Images

Company Profile

About us:

Established in 2011,Bengbu Tongchen Automation Technology Equipment

CO.,LTD, is a specialized firm that integrates research,

development, manufacturing, marketing and after-sales service for

filtration equipment manufacturing equipment. Our primary product

offerings encompass a range of advanced machinery, including but

not limited to fully automated reciprocating paper folding

production lines, fully automated PP intermittent glue injection

and wave reception production lines, fully automated paper frame

gluing production lines.For more information or to schedule a

demonstration, please contact us. We are committed to providing

tailored solutions that meet the unique needs of our clients.

Product packaging

FAQ

Can you give me a discount price?

It is depending on the volume. The larger the volume is, the more

discount you can enjoy.

How do you guarantee your quality ?

Our workers and technical employees are with many years experiences

to ensure the products are good.

After production finished,check will be made by quality inspector.

How about your after-sales service?

We have a professional technical service team to provide online

guidance.

Company Profile

Your Trusted Partner in Filter Manufacturing Automation!

Founded in 2011, Tongchen is a leading Chinese manufacturer

specializing in R&D, design, and production of filter manufacturing equipment. Headquartered in Bengbu—known as the "Pearl City" and a key

industrial hub—we integrate advanced technology with lean

manufacturing to deliver innovative solutions for global filter

industries.

Our Mission: Develop high-efficiency, reliable equipment that meets international standards, empowering customers to excel

in air/water filtration and environmental protection markets.

Our Advantages

- Eco-Friendly Design: Adhesive-Free Bonding Technology enables pollution-free

production.

- Enhanced Efficiency: Automated manual processes elevate production speed by up to 40%.

- Expanded Capabilities: Flexible modular designs facilitate the addition of new product

lines (e.g., HEPA filters, industrial dust collectors).

- Cost Reduction: Low energy consumption and minimal maintenance needs decrease

long-term operational costs.

We offer a full suite of filter manufacturing solutions,

categorized into 5 core series:

- Paper Pleating Machines

High-precision servo-driven systems for air/liquid filter materials

(filtration efficiency: ISO 16890/EN 779 compliant). - Mask Making Machines

Full-automatic lines producing 3-ply masks, N95/KN95 (output:

80-120 pcs/min). - Automotive Filter Machines

- Cabin Air Filter Machines: Customized for OEM standards (e.g.,

Japanese automotive specs).

- PU Air Panel Filter Machines: For high-efficiency particulate air

(HEPA) filters.

- Spin-On Filter Production Lines

Integrated solutions for oil/fuel filters (assembly accuracy:

±0.1mm).

- Air Filtration

- HEPA/ULPA Filters: Efficiency up to H14 (EN 1822).

- Heavy-Duty Filters: Designed for construction machinery (dust

resistance: ≥99.5%).

- Liquid Filtration

Fuel filters (ISO 4548 certified) and hydraulic system elements. - Eco-Filters: Recyclable materials compliant with EU REACH standards.

- Filter Performance Test Benches

- Air Filters: Measures efficiency (ISO 16890), pressure drop (EN

779).

- Oil/Fuel Filters: Tests dirt-holding capacity (ISO 19438) and burst

pressure.

- Material Testing Instruments: For fabric permeability, tensile strength (ASTM D737).

- Edge Trimming/Cutting Machines: Precision cutting to ±0.5mm tolerance.

- Cross-Cutting Machines: Automatic length control for filter media (speed: 10-50m/min).

- Edge Pasting Machines: High-speed adhesive application (bond strength: ≥2N/mm).

- Smoke Detection Benches: Real-time filtration efficiency analysis (0.1-10μm particle

detection).

- OEM/ODM Services: Tailored to specific industry standards (e.g., automotive,

aerospace).

- Turnkey Projects: From material feeding to quality control, fully integrated

production lines.

Retrofit Upgrades: Modernize existing equipment with smart control systems (e.g.,

PLC upgrades).

- Certifications: CE, ISO 9001:2015, and industry-specific approvals (e.g., IATF

16949 for automotive lines).

- Export Markets: Sold in 20+ countries across North America, Europe, Southeast

Asia, and the Middle East.

- Service Promise:

- 24/7 Technical Support: Remote diagnostics via IoT-connected systems.

- Spare Parts: 48-hour worldwide delivery for critical components.

- Training: On-site operation workshops and online courses.

- Innovation: 12+ patents in servo control and intelligent manufacturing.

- Quality: 100% pre-shipment testing (3-step QC process: material inspection

→ assembly test → full-load run).

Sustainability: Energy-efficient designs (≤15% power consumption vs. traditional

models).

Whether you need a single machine or a full production line,

Tongchen provides engineering expertise and responsive service to drive your success.

"Precision Engineering, Global Filtration Solutions"