Add to Cart

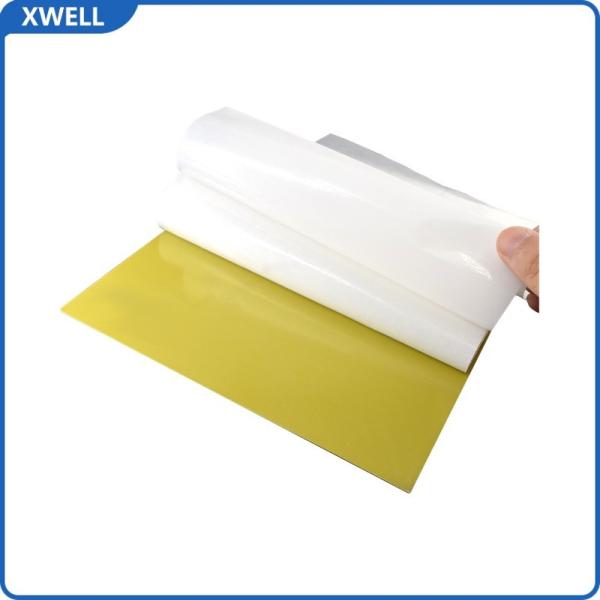

In battery pack assembly, insulation failure due to high temperature or moisture can lead to short circuits and safety risks. Our Yellow 3240 Epoxy Board solves this critical pain point: as a dedicated battery pack insulation board, it combines exceptional high-temperature resistance, strong moisture resistance, and reliable electrical insulation—making it ideal for lithium-ion, LiFePO4, and lead-acid battery packs in EVs, energy storage systems, and industrial equipment. The bright yellow color also enables easy visual inspection during assembly, reducing quality control errors.

| Advantage | Key Benefit for Battery Pack Manufacturers |

|---|---|

| Extreme High-Temp Resistance | Withstands continuous use at 130℃ (short-term up to 180℃), avoiding deformation or insulation breakdown in high-heat battery operating environments. |

| Strong Moisture Resistance | Water absorption rate ≤0.1% (24h immersion test), maintaining insulation performance even in humid or outdoor energy storage scenarios. |

| Reliable Electrical Insulation | Volume resistivity ≥10¹⁵ Ω·cm, dielectric strength ≥18 kV/mm—effectively isolating positive/negative electrodes to prevent short circuits. |

| Mechanical Durability | Tensile strength ≥80 MPa, flexural strength ≥120 MPa; resistant to impact and vibration during battery pack transport and use. |

| Easy Assembly & Inspection | Bright yellow color enables quick visual checks for missing or misaligned boards; easy to cut, drill, and punch to match custom battery pack sizes. |

| Specification | Details | Test Standard |

|---|---|---|

| Product Model | 3240 Epoxy Glass Cloth Laminate | IEC 60893-3-2 |

| Color | Standard bright yellow (custom colors available on request) | Visual inspection |

| Temperature Resistance | Continuous operating temp: 130℃; Short-term temp: 180℃ | GB/T 1303.1 |

| Moisture Resistance | Water absorption rate: ≤0.1% (24h, 23℃ distilled water) | IEC 60893-2-1 |

| Electrical Performance | - Volume resistivity: ≥10¹⁵ Ω·cm (23℃) - Dielectric strength: ≥18 kV/mm (23℃) - Dielectric constant: 4.5 (1 MHz) | IEC 60250; IEC 60243-1 |

| Mechanical Performance | - Tensile strength: ≥80 MPa (longitudinal) - Flexural strength: ≥120 MPa (longitudinal) - Impact strength: ≥15 kJ/m² | GB/T 1040.4; GB/T 9341; GB/T 1043.1 |

| Standard Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm, 3.0mm, 5.0mm | GB/T 1303.1 |

| Standard Size | 1000mm*2000mm, 1220mm*2440mm (custom sizes cuttable) | Customizable |

Our Yellow 3240 Epoxy Insulation Board is a must-have for battery pack safety across industries, where insulation reliability directly impacts product lifespan and safety:

To fit your specific battery pack design, we offer flexible customization and pre-processing options:

| Service Type | Available Options |

|---|---|

| Size Cutting | Cut to custom dimensions (minimum 50mm*50mm) with ±0.1mm precision |

| Hole Drilling | Pre-drilled mounting holes (M2–M10) or positioning holes—per your CAD drawings |

| Edge Processing | Deburred edges (to avoid damaging battery components) or chamfered edges (for easy assembly) |

| Surface Treatment | Anti-static coating (optional, for electronics-grade battery packs) |

| Packaging | Standard: PE film + cartons; Custom: Vacuum packaging (for long-distance shipping) or wooden crates (for bulk orders) |

If you need to confirm the right thickness or size for your battery pack, send us your assembly drawings—our engineering team will provide free recommendations. Contact us today for a detailed quote!