Add to Cart

1. Unique Ultra-Large Aperture Structure

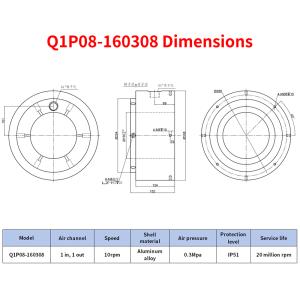

The large aperture design provides an exceptionally large

through-hole space of 160mm inner diameter (308mm outer diameter),

offering improved accessibility and layout flexibility for central

shafts, main pipelines, or wiring harness integration in large

equipment.

2. Lightweight and Robust

The housing is constructed of a lightweight alloy, ensuring

structural strength and reliability while effectively controlling

product weight, making it easier to install and integrate into

large equipment.

3. Designed for High-Flow Gas Transmission

The single-channel design with one inlet and one outlet features a

standard G1” internal thread, allowing direct connection to a 25mm

diameter gas line to meet high-flow gas transmission needs.

4. Compatibility with Specific Media and Operating Conditions

This product is suitable for nitrogen media, operating at a

pressure of 0.3 MPa and a rotational speed of 10 RPM. It is

designed for low-speed, heavy-load applications, enhancing its

stability and reliability in large, slow-moving rotating equipment.

| Parameter | Value |

|---|---|

| Transmission medium | Nitrogen (liquid available by customization) |

| Working life | 20 million revolutions (reference value) |

| Maximum speed | 10 RPM |

| Pressure range | 0.3MPa |

| Operating temperature | -30℃ to +80℃ |

| Operating humidity | 0-85% RH |

| Protection level | IP51 |

| Shell material | Aluminum alloy |

| Rotational torque | 0.5N.m (reference value, torque increases with channel count) |

This product is designed to address the unique needs of large, low-speed rotating equipment requiring high-volume, high-throughput gas flow through the center structure. It is primarily targeted at the following heavy-duty industrial sectors:

1. Chemical and Pharmaceutical Processes

Applications: Rotating agitator shafts in large reactors/mixing tanks, and rotary dryers.

Solution: Nitrogen (N₂) is injected into sealed containers through a hollow shaft core for inert gas protection, pressurization, or purging during the process, preventing material oxidation, or controlling the reaction environment.

2. Metallurgy and Heat Treatment

Applications: Rotating mechanisms for the lid or crucible of large furnaces, and rotating components in continuous annealing lines.

Solution: During heat treatment, nitrogen is introduced to create a protective atmosphere to prevent oxidation of metal materials at high temperatures. The large aperture facilitates the passage of cables for monitoring components such as thermocouples.

3. Heavy Machinery and Large-Scale Testing Equipment

Applications: Rotating spindles in large bearing testing machines, and certain large rotating test platforms for wind turbines. Solving Needs: Providing nitrogen for cooling or sealing rotating parts. The large central aperture is also used for routing hydraulic piping, main cables, and other components, enabling complex functional integration.

4. New Energy and Materials Manufacturing

Applications: Lithium battery sintering furnaces and rotating units

in large composite molding equipment.

Solving Needs: Providing a stable, clean inert gas environment

during precision manufacturing processes to ensure product quality.