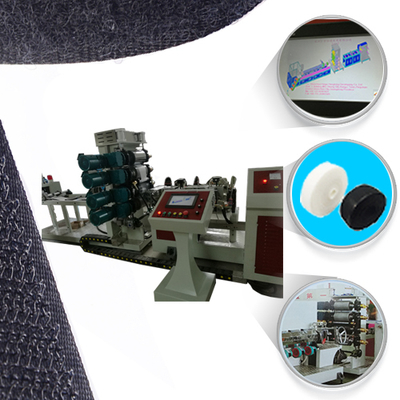

The HHD Series Injection Hook Production Line is a specialized,

high-efficiency system designed for producing Velcro plastic hook

tapes. It employs advanced extrusion technology and a unique mold

rolling process, fully compatible with materials such as PP, PA6,

PE, PVC, TPU, and other nylon-based compounds.

This production line is configured with #2, #3, and #4 molds,

supported by auxiliary devices including a dehumidifier dryer,

mixer, edge material grinder, and sub-machines. These components

form an integrated system enabling continuous, stable, and

intelligent plastic hook manufacturing.

The extruder utilizes Japan RKC PID temperature controllers, along

with melt pressure and temperature sensors. The drive system

incorporates ABB frequency inverters and a Siemens control unit

from Germany, ensuring efficient and reliable performance.

The sheet three-roll polishing machine features quenched mirror

rolls (customizable upon request), each powered by independent

frequency-controlled motors. The die head adopts a hanger-style

structure, and the winding method is center coiling, ensuring

smooth and even sheet formation.

The calender rollers are heated via a water heating system for

consistent operation. Our company also offers complete

customization to meet different client requirements. Currently, we

supply to numerous domestic and international granulation and

finished product manufacturers. Available models range in width

from 100 to 600mm and extrusion capacity from 5 to 250kg/h.

Machine Technical Data - Sheet Extrusion Line

| Specification | HY-VT160 | HY-VT300 |

|---|

| Linear speed | 10~25 m/min | 10~25 m/min |

| Extrusion capacity | 50-80 kg/h | 150 kg/h |

| Sheet thickness | 0.2-2 mm | 0.3-1.8 mm |

| Max width | 160 mm | 160 mm |

| Principal motor power | 70 kW | 230 kW |

| Monitoring | Transducer control | Transducer control |

| Air pressure | 6 bar | 6 bar |