Add to Cart

| Process Stage | Specification |

|---|---|

| Primary Manufacturing | High Pressure Die Casting (HPDC) |

| Materials Available | ADC12, A380, Zamak 3/5, Magnesium alloys |

| CNC Finishing | 3-axis / 5-axis CNC machining (±0.02 mm tolerance) |

| Surface Treatments | Anodizing (Type II/III), Powder Coating, ED Coating, Sandblasting, Polishing |

| Surface Finish Options | Matte, Glossy, Textured, Brushed, Metallic |

| Coating Thickness | Anodizing: 10–50μm; Powder: 60–120μm |

| Corrosion Resistance | Up to 1000 hours salt spray (ASTM B117) |

| Waterproof Rating (Optional) | IP65–IP67 (with sealing treatment) |

| Lead Time | Prototypes: 5–7 days; Mass Production: 15–30 days |

| Standards Compliance | IATF 16949, ISO 9001, RoHS, REACH |

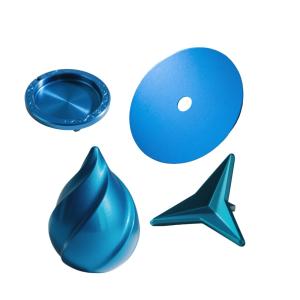

Integrated Die Casting & CNC Machining

Save time and cost with end-to-end production: from raw casting to

precision machining under one roof.

Multi-Stage Surface Treatment Options

Enhance corrosion resistance, electrical insulation, or aesthetics

with anodizing, powder coating, or ED coating—all in-house.

Tight Tolerance Machining

CNC post-processing ensures that every functional feature meets

±0.02 mm precision.

Flexible for Custom Projects

Whether it’s small runs for prototypes or high-volume production,

our workflow adapts to your project’s complexity and scale.

Enhanced Durability & Finish

Surface treatments not only improve appearance but also provide

abrasion, UV, and chemical resistance.

Eco-Friendly Coatings

Adoption of low-VOC powder coatings and chrome-free anodizing

technologies for greener compliance.

Smart Surface Engineering

Functional coatings such as anti-fingerprint, EMI shielding, and

heat-dissipative anodizing layers.

Digital Color Matching & QC

Automated systems for consistent RAL color reproduction, gloss

level, and texture repeatability.

Advanced Hybrid Finishes

Combination of anodizing + CNC engraving or powder coating + laser

etching for premium product branding.

Consumer Electronics Housings

Sleek, anodized or powder-coated aluminum shells for handheld

devices, smart home products, and wearables.

Automotive Trim & Mounting Components

Die cast brackets, mounts, and interior trim parts with durable

finishes that match OEM quality standards.

Industrial Enclosures & Interfaces

Rugged CNC-machined aluminum with IP-rated coatings for electrical

boxes, PLC casings, and machine covers.

Medical Devices

Sterile, corrosion-resistant aluminum parts for lab instruments,

housings, and handles.

Aerospace & UAV Systems

Lightweight structural parts requiring both precision and

resistance to harsh environments.

Q1: What is the benefit of using CNC after die casting?

A1: CNC machining ensures high precision for critical features such

as threads, flatness, and tight tolerances not achievable through

casting alone.

Q2: Can I customize the surface treatment color and texture?

A2: Yes. We offer custom RAL color matching, matte/gloss levels,

and textures including brushed, bead-blasted, and polished

finishes.

Q3: How durable is the surface treatment?

A3: Anodized and powder-coated parts can withstand up to 1000 hours

of salt spray testing. We follow ASTM and ISO standards for

durability.

Q4: Do I need to use multiple suppliers for machining and coating?

A4: No. We offer a fully integrated solution including die casting,

CNC finishing, and all major surface treatments—saving time and

cost.

Q5: What’s the typical lead time for a new part?

A5: Prototypes can be ready in 5–7 days. Mass production generally

takes 15–30 days depending on volume and complexity.

Q6: Can you provide design support for manufacturability?

A6: Absolutely. Our engineering team assists with DFM analysis to

ensure optimal casting, machining, and surface finish performance.

Streamline Production with a Single Supplier for Die Cast, CNC, and

Surface-Finished Aluminum Parts

From raw casting to precision machining and premium surface

treatment, we deliver a complete solution to bring your aluminum

components to life—faster, cleaner, and better. Request a quote

today.