Product Details

Product Overview:

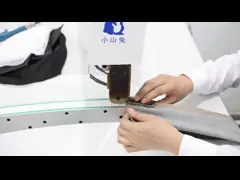

The Top & Bottom Edge Stitching Machine, also known as a Garment

Edge Trimming Machine, is a high-performance specialized sewing

equipment designed for precision finishing in garment production.

It is primarily used for stitching top and bottom edges of key

garment sections such as plackets and collars—particularly in

suits, overcoats, jackets, and other mid-to-high-end apparel—to

achieve clean and decorative seams with exceptional efficiency and

accuracy.

Key Features:

- Extensive Fabric Adaptability: Capable of efficiently processing fabrics of varying thicknesses

and materials, effortlessly handling everything from light to

medium-weight textiles while ensuring even and aesthetically

pleasing stitches.

- Fully Automatic Oil Supply System: Equipped with an automatic oiling mechanism that significantly

reduces maintenance needs, enhances equipment durability, and

ensures long-term operational stability.

- High-Precision Edge Stitching: Supports a standard 3mm edge stitching width, delivering accurate

and neat seams that greatly improve the detailed finish and

consistency of garments.

- Intelligent Control and Stability: Features an integrated automated control system for user-friendly

operation and stable fabric feeding, making it ideal for precision

processing of mid-to-high-end apparel such as suits and coats.

- Efficient Production and User-Centered Design: Enhances production efficiency while maintaining high-quality

stitching results, reduces manual operation effort, and meets the

demands of modern garment manufacturing.

Product Parameters:

Model | SXT-103N-3 |

Sewing speed | 2000 stitches/min |

Max lift of the presser foot | 6/10mm |

Trimming width | 3mm |

Oil feeding | Automatic |

Motor power | 0.55kW |

Power | 220V 50Hz |

Application:

Company Profile

Since its founding in 2018 and based in Yangchenghu Town,

Xiangcheng District, Dressed Santo Intelligent Sewing Co., Ltd. has adhered to a clear development philosophy from the very start — "Taking innovation as the foundation, technology as the core, and

quality for growth". Guided by this principle, the company has focused on addressing

pain points in the garment sewing industry, and as a professional

equipment manufacturer, it has continuously injected new vitality

into the sector’s advancement.

Deeply committed to R&D and production of garment sewing

equipment, the company’s product portfolio covers key links in the

sewing process, including intelligent double-faced wool interlining

strip ironing machines, steam-free interlining strip ironing

machines, side-seam hand sewing machines, middle-seam hand sewing

machines, button attaching machines, and pocket opening machines.

Among these, the steam-free interlining strip ironing machine stands out as a

world-first innovation — a product developed entirely through independent R&D, a

direct embodiment of the company’s "innovation-driven" philosophy.

This groundbreaking equipment not only fills an industry gap but

also underscores the company’s technological prowess; to date, it

has secured over 50 national patents, a testament to how the

"technology-centric" principle translates into tangible competitive

advantages.

Since its inception, the "innovation-technology-quality" philosophy

has served as the core engine for the company’s growth. It has

driven continuous product iteration and upgrades, enabling Dressed Santo to achieve remarkable progress in just a few years. In 2019, the

company officially launched its independent brand "Dressed Santo". Upholding the philosophy’s focus on quality, "Dressed Santo" quickly gained prominence in the market, earning high recognition

from both industry insiders and clients. Today, leveraging the

reliability shaped by its quality-focused approach, the company’s

products are not only bestsellers in major domestic garment

industry hubs but also have won consistent acclaim for their

performance and service. As a result, Dressed Santo has become a trusted partner for garment enterprises seeking to

boost efficiency and optimize sewing processes — all rooted in its

unwavering commitment to its founding development philosophy.