Product Details

Product Overview:

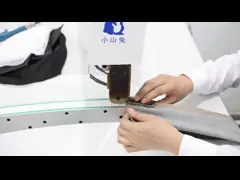

The automatic button sewing machine is an automated sewing device

primarily used to quickly and accurately attach buttons to various

fabrics (such as clothing, home textiles, and luggage). It is

widely used in mass production in the textile and apparel industry.

By integrating its mechanical structure with an electronic control

system, it replaces traditional manual or semi-automatic button

sewing methods, significantly improving production efficiency and

ensuring consistent button quality.

Key Features:

l The system automatically completes the entire button sewing

process, including gripping, positioning, threading, and knotting.

l It adapts to various button types (such as snap buttons, press

studs, resin buttons, and metal buttons) and fabrics (cotton,

linen, synthetic fiber, and leather).

l It supports a variety of button sewing styles, including

single-hole, double-hole, and four-hole styles, and can adjust

parameters such as stitch length and stitch density to meet your

needs.

Product Parameters:

Stitch type | Single-thread chain stitch |

Sewing speed | Max. sewing speed | 1800 sti/min (neck-wrapping); 1200 sti/min (button sewing) |

Normal sewing speed | 1500sti/min (neck-wrapping); 1000sti/min (button sewing) |

Application | Sewing of various button types |

Button size | Sewing button without neck-wrapping: φ8~φ38mm

Sewing button with neck-wrapping: φ8~φ32mm

Counter button: φ8~φ25mm |

Display screen for setting basic shape-setting | Distance between buttonholes:1.5~6.0mm (in increments of 0.1mm)

Height of neck-wrap:0,1.5~10.0mm (in increments of 0.1mm)

Number of cross-over stitches:2~64 (in increments of 2) |

Number of data that can be input | Max. 99 patterns |

Number of cycle stitch patterns | The number of registered patterns:20 (30 patterns for one cycle) |

Languages supported for operation panel | English, Español, Italiano, Français, Deutsch, Português, Türkçe, Việt nam, 한국어, Indonesia, Ρycckий |

Application:

It is widely used in the mass production of shirts, jackets, jeans,

children's clothing, bags, tents and other products. It is one of

the indispensable key equipment in the industrial production of

clothing.

Company Profile

Since its founding in 2018 and based in Yangchenghu Town,

Xiangcheng District, Dressed Santo Intelligent Sewing Co., Ltd. has adhered to a clear development philosophy from the very start — "Taking innovation as the foundation, technology as the core, and

quality for growth". Guided by this principle, the company has focused on addressing

pain points in the garment sewing industry, and as a professional

equipment manufacturer, it has continuously injected new vitality

into the sector’s advancement.

Deeply committed to R&D and production of garment sewing

equipment, the company’s product portfolio covers key links in the

sewing process, including intelligent double-faced wool interlining

strip ironing machines, steam-free interlining strip ironing

machines, side-seam hand sewing machines, middle-seam hand sewing

machines, button attaching machines, and pocket opening machines.

Among these, the steam-free interlining strip ironing machine stands out as a

world-first innovation — a product developed entirely through independent R&D, a

direct embodiment of the company’s "innovation-driven" philosophy.

This groundbreaking equipment not only fills an industry gap but

also underscores the company’s technological prowess; to date, it

has secured over 50 national patents, a testament to how the

"technology-centric" principle translates into tangible competitive

advantages.

Since its inception, the "innovation-technology-quality" philosophy

has served as the core engine for the company’s growth. It has

driven continuous product iteration and upgrades, enabling Dressed Santo to achieve remarkable progress in just a few years. In 2019, the

company officially launched its independent brand "Dressed Santo". Upholding the philosophy’s focus on quality, "Dressed Santo" quickly gained prominence in the market, earning high recognition

from both industry insiders and clients. Today, leveraging the

reliability shaped by its quality-focused approach, the company’s

products are not only bestsellers in major domestic garment

industry hubs but also have won consistent acclaim for their

performance and service. As a result, Dressed Santo has become a trusted partner for garment enterprises seeking to

boost efficiency and optimize sewing processes — all rooted in its

unwavering commitment to its founding development philosophy.