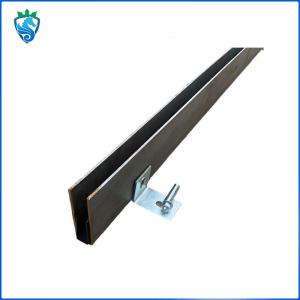

Balcony Tinted Black Aluminum Handrail Profile U Channel Clamp Glass Railing

Add to Cart

Balcony Tinted Black Aluminum Profile U Channel Clamp Glass Railing Handrail

Basic Information

|

|

| Aluminum |

|

|

|

|

|

|

| square/ as customer's requestments |

|

|

Product Display

The phenomenon of twisting along the longitudinal axis of aluminum

profiles in the extrusion process of one part and another part is

different from the outflow speed; generally, the non-axisymmetric

aluminum profiles are easy to produce, and both solid and hollow

profiles may be produced, and some are produced at the beginning. ,

and some occur at the end of extrusion; the main reason is that the

flow speed of each part of the aluminum profile is different when

it passes through the die; when this defect is slight, it can be

corrected in the subsequent straightening process, and when the

twisting is serious , it cannot be eliminated even by

straightening;

Elimination method:

1) Correct the length of the mold sizing belt to make the aluminum

profile flow evenly;

2) Reasonable design of the shunt hole and bridge structure for the

hollow mold;

3) Place a similar-shaped guide at the exit of the aluminum

profile, or press the aluminum profile with a graphite plate or

graphite strip to make it advance smoothly;

4) Reasonably adjust the extrusion temperature and extrusion speed

to make the deformation uniform;

Application of aluminum profiles:

1. Architectural aluminum profiles (divided into doors and windows

and curtain walls).

2. radiator aluminum profiles.

3. General industrial aluminum profiles: mainly used for industrial

production and manufacturing, such as automated machinery and

equipment, the skeleton of the cover, and the company's customized

mold opening according to their own mechanical equipment

requirements, such as assembly line conveyor belts, elevators, glue

dispensers, Testing equipment, shelves, etc., are mostly used in

the electronic machinery industry and clean rooms.

4. Aluminum alloy profiles for rail vehicle structure: mainly used

in the manufacture of rail vehicle body.

5. Mounting aluminum profiles, making aluminum alloy picture

frames, mounting various exhibitions and decorative paintings.

Certificates and Honors

Company Profile

Jiangyin Longkang Metal Products Co., Ltd. is located in Zhouzhuang

Town, Jiangyin City - the largest aluminum extrusion profile

production base. Covering an area of more than 35,000 square meters

with more than 350 employees. We focus on metal customization,

special-shaped aluminum profiles, aluminum profiles, aluminum

tubes, rail transit series, doors and windows aluminum profiles,

heat sinks, CNC processed aluminum profiles, interior decoration

series, bending series, etc. We also have precision anodizing and

various surface treatments, such as PVC film, wood grain,

electrophoresis, powder coating, anodizing, etc. After more than 20

years of development, The company has become a modern aluminum

production enterprise with perfect quality management system.

The company has the ability to develop and design molds

independently, we can produce any extruded aluminum profiles

according to your mechanical drawing or sample. Longkang has 10

extrusion production lines (600-3500 tons), one automatic oxidation

electrophoresis production line, vertical and horizontal spraying

production line per each, and a variety of advanced supporting

production, processing and testing equipments. There are also CNT

digital control drilling and milling machine(CNC), double head saw,

hydraulic saw and punching machine in our processing workshop. The

complete technological process can benefit to reduce the production

turnover times for semi-finished products, to avoid the damage

during transportation, improve the production efficiency, reduce

the cost of production,and to ensure the quality and delivery time.

Efficiently treating our customers as partners with sincerity,

specialization and satisfaction is our managerial principle.

Attributed to the backup of a dedicated technical team, filled with

wide and profound knowledge and practice in aluminum profile and

world trade for 20 years, the company owns rich experience in

product quality control and profile physical properties such as

Hardness, Stretchability, Flatness, Straightness, and Tolerance

etc. In line with the principle of sharing the preferential cost

and joint development, the company has formed an interest community

for years with its customers at home and abroad. Sincerely to build

up a pleasant mutual trust, cooperative, win-win and value-added

sustainable partnership is what we are achieving to grow together

with you!

Factory display

FAQ

Q:Do you provide samples?

A: Yes (special customized samples need to provide drawings.

Q: What about the delivery time?

A: Average 12 working days, 7 days for mold opening, 10 days for

mass production

Q: How do you ship your goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. Usually it takes 3-5

days to arrive. Air and sea shipping are also optional.