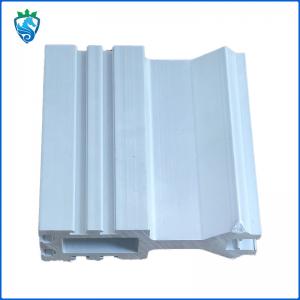

Sliding Boat Aluminium Window Profiles Square Tube 20x20 80 20 100x100

Add to Cart

Profil Square Tube Aluminum Profile Kitchen Cabinet Aluminium

Window Profiles

Basic Information

|

|

| Aluminum-wood |

|

|

|

|

|

|

| As customer's requestments |

|

|

Product Display

Door and window safety design

⒈The wall thickness of aluminum profiles for doors and windows

requires that the wall thickness of aluminum profiles for windows

conform to the current national standard high-precision grade, and

the minimum wall thickness of the stressed components is ≥1.4mm.

⒈ The force-bearing rods of doors and windows (such as the light

hook of sliding window, the central column, the sliding with light,

the sliding with light, the double front, etc.) must undergo strict

compression calculation. Thickness should be selected by

calculation according to usage conditions. The stress components of

aluminum alloy doors and windows shall be determined by test or

calculation.

⒉ Door and window glass safety design

(1) Selection of glass: The thickness of glass is determined by

calculation and should not be less than 5mm. Safety glass (tempered

glass or laminated glass) must be used for doors and windows in the

following parts of the building:

(a) Opening windows outside buildings with 7 floors and above;

(b) Window glass with an area greater than 1.5 square meters;

(c) Floor-to-ceiling windows with the bottom edge of the glass less

than 500mm from the final decoration surface;

(d) Sloping windows with an included angle of less than 75° from

the horizontal and a sloped roof greater than 3m from the indoor

floor;

(e) Framed glass doors with a glass area greater than 0.5 square

meters;

(f) The frameless glass door shall be made of tempered glass with a

thickness of not less than 10mm.

(2) The overlap between the glass and the notch and other matching

dimensions shall comply with the provisions of Table 5 and Table 6

in "Aluminum Alloy Window" (GB/T 8479).

(3) The glass and aluminum alloy frame grooves should be in

flexible contact with rubber gaskets.

⑷The glass should be subjected to mechanical edging treatment, and

the mesh number of the grinding wheel should be more than 180

meshes.

⒊The selection and design of hardware accessories.

(1) When choosing hardware accessories, try to choose products with

guaranteed quality. The quality grade of hardware accessories

should be consistent with the quality grade of doors and windows.

The structure and shape of hardware accessories should be

consistent with the profiles. The color is harmonious and

beautiful, the function is correct, and the operation is flexible.

, Easy to install.

(2) The installation of hardware accessories should be complete,

standardized, reliable and accurate. After installation, the doors

and windows are beautiful in appearance, flexible and convenient to

open, free from deformation, obstruction and collision.

(3) Exposed fasteners of hardware accessories should preferably use

stainless steel products.

(4) Casement doors and windows and large sliding doors and windows

should be closed with multiple lock points, otherwise the air

tightness will be greatly reduced under the action of negative

pressure difference. Considering the convenience of operation, it

is best to use multi-lock point handles or actuators.

⑸ The length of the sliding brace of the casement window is

generally 2/3 of the width of the window sash. If the window sash

is lighter, it can be 1/2. The length of the sliding brace of the

upper-hung window is generally 1/2 of the window sash.

⑹For typhoon areas and high-rise buildings to open windows, it is

recommended to use sliding braces for window sash installation, and

no or less hinges are used.

⒋The overlap between the sliding door and window sash and the upper

and lower frame guide rails should not be less than 10mm, and

safety measures such as anti-fall blocks and anti-collision blocks

must be installed to prevent the sash from falling and colliding

and hurting people when it is opened.

⒌The height of the lower frame of the glass window movable fan on

the exterior wall of the building should not be less than 900mm

from the indoor ground. Under special circumstances, if it is less

than 900mm, other protective safety measures (such as adding

protective railings, etc.) should be taken.

⒍The screws and bolts used for the connection and fixation of

aluminum alloy doors and windows must be made of high-quality

stainless steel to prevent the screws from loosening due to

galvanic corrosion. Stainless steel screws should be made of

machine-made threads as much as possible, and self-tapping screws

should be avoided as much as possible.

⒎ Doors and windows should be reliably connected and fixed with the

wall

The connection methods between doors and windows and walls mainly

include steel frame connection, dovetail iron foot welding

connection, dovetail iron foot connection with embedded parts,

fixed steel sheet nailing connection, fixed steel sheet metal

expansion bolt connection and so on. The thickness of dovetail iron

feet should be ≥3mm. The thickness of the fixed steel sheet is

≥1.5mm, and the width is ≥15mm. All dovetail feet and fixed steel

surfaces shall be hot-dip galvanized. The distance between the

fixed points of doors and windows is generally between 300mm and

500mm, and cannot be greater than 500mm.

(1) Steel attached frame is suitable for the connection between

doors and windows and various walls, with high installation

accuracy and reliable connection, but the cost is high.

(2) The connection between the doors and windows and the steel

structure can be welded by dovetail iron feet, and the connection

between the dovetail iron feet and the steel structure can be

adjusted by welding steel bars or steel angle codes.

(3) The connection between the doors and windows and the light wall

should adopt the welding connection method between the dovetail

iron feet and the embedded parts, and the dovetail iron feet and

the embedded parts should be adjusted by welding with steel bars or

steel angle codes.

⑷The connection between doors and windows and reinforced concrete

walls can be connected with fixed steel sheets (or dovetail iron

feet) or metal expansion bolts. When using fixed steel sheets to

connect fixed doors and windows, the gap between the frame around

the door and the wall and the wall should be plugged with cement

mortar. Cement mortar plug joints can connect the outer frame of

doors and windows to the wall firmly and reliably, and play an

important role in strengthening the frame materials of doors and

windows. When the gap is filled with polyurethane foam caulk or

other flexible materials, the fixed steel sheet should be replaced

with dovetail iron feet to ensure the reliability of the connection

between doors and windows and walls.

⑸The connection between the doors and windows and the brick wall

can be connected by metal expansion bolts with fixed steel sheets

(or dovetail iron feet). It is strictly forbidden to use nails to

fix doors and windows on brick walls. Like reinforced concrete

walls, when using fixed steel sheets, the gaps should be plugged

with cement mortar, and when the gaps are filled with polyurethane

foam sealants or other flexible materials, they should be fixed

with dovetail iron feet.

Certificates and Honors

Factory display

Company Profile

Jiangyin Longkang Metal Products Co., Ltd. is located in Zhouzhuang

Town, Jiangyin City - the largest aluminum extrusion profile

production base. Covering an area of more than 35,000 square meters

with more than 350 employees. We focus on metal customization,

special-shaped aluminum profiles, aluminum profiles, aluminum

tubes, rail transit series, doors and windows aluminum profiles,

heat sinks, CNC processed aluminum profiles, interior decoration

series, bending series, etc. We also have precision anodizing and

various surface treatments, such as PVC film, wood grain,

electrophoresis, powder coating, anodizing, etc. After more than 20

years of development, The company has become a modern aluminum

production enterprise with perfect quality management system.

The company has the ability to develop and design molds

independently, we can produce any extruded aluminum profiles

according to your mechanical drawing or sample. Longkang has 10

extrusion production lines (600-3500 tons), one automatic oxidation

electrophoresis production line, vertical and horizontal spraying

production line per each, and a variety of advanced supporting

production, processing and testing equipments. There are also CNT

digital control drilling and milling machine(CNC), double head saw,

hydraulic saw and punching machine in our processing workshop. The

complete technological process can benefit to reduce the production

turnover times for semi-finished products, to avoid the damage

during transportation, improve the production efficiency, reduce

the cost of production,and to ensure the quality and delivery time.

Efficiently treating our customers as partners with sincerity,

specialization and satisfaction is our managerial principle.

Attributed to the backup of a dedicated technical team, filled with

wide and profound knowledge and practice in aluminum profile and

world trade for 20 years, the company owns rich experience in

product quality control and profile physical properties such as

Hardness, Stretchability, Flatness, Straightness, and Tolerance

etc. In line with the principle of sharing the preferential cost

and joint development, the company has formed an interest community

for years with its customers at home and abroad. Sincerely to build

up a pleasant mutual trust, cooperative, win-win and value-added

sustainable partnership is what we are achieving to grow together

with you!

FAQ

Q: Can you send me the product catalog and price?

A: Leave your e-mail or other contact information, the product

catalog will be provided here

The real-time price needs to confirm the specific product

specifications and quantity, so the price can be calculated for you

only when you provide drawings or plans, etc.

Q: Do you provide samples?

A: Yes (special customized samples need to provide drawings).

Q: What is the thickness of the anodizing? Can you do 12um?

A: Our normal thickness is about 10 um. Yes, we can do 15 microns

and above.