Add to Cart

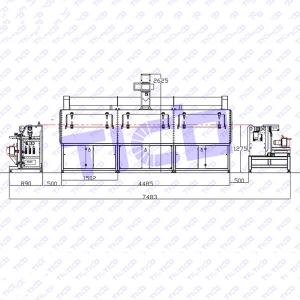

Slot Die Roll to Roll Electrode Film Coating Machine with Three

Drying Chamber for Battery Production

Product Introduction

This machine is applied in Lithium-ion battery electrode coating process of cathode & anode. The slot extrusion coating die is used for non-contact coating to substrate, which can realize the continuous, intermittence, stripe film coating and etc. This machine owns the higher coating precise, consistency and stability, it also can be applied in the others slurry and substrate film coating.

Features

• Extrusion coating process, high precise.

• The temperature of each drying oven can be controlled

independently.

• The qty and dimension of drying oven can be customized according

to requirement.

• Modular design, easier to install.

• Wider roller, it is the ideal of machine for small pilot line.

• Continuous, intermittence film coating model can be changed

freely.

Technical Parameter

| Model | STC-TMJ-500F3 | |

| Substrate thickness | Aluminum foil: 0.010~0.030mm Copper foil: 0.006~0.030mm | |

| Substrate width | Aluminum foil: 100~350mm Copper foil: 100~350mm | |

| Max. wet thickness of coating | 80~40µm (on the basis of satisfying the slurry viscosity requirements) | |

| Max width of coating | 330mm | |

| Max width of coating roller | 500mm | |

| Mechanical conveying speed | 0.5~7m/min | |

| Coating speed | 0.5~1.2m/min (it various based on different slurries) | |

| Oven length | 3 oven×1.5m/oven, total 4.5m. Oven qty can be available. | |

| Voltage | 380V | |

| Drying form | Hot air drying | Hot air circulation (upper and lower air supply |

| Heating method | Electric heating 4.8KW×3 sections, total 14.4KW | |

| Oven material | Oven is made of stainless steel, both internally and externally | |

| Oven temperature | RT~150℃, adjustable. Accuracy, <±5℃ | |

| Coating accuracy | Accuracy error of dry thickness | Single-sided anode: ±2.0µm, cathode: ±2.0µm |

| Alignment error of two sides coating | ≤±1.0mm | |

| Average length error | ≤±1.0mm | |

| Average width error | ≤±1.0mm | |

Warranty

1 year warranty with lifetime support. Man-made damage is not

included.

FAQ

1. Are you a manufacturer?

A: Yes, our factory is located in Shenzhen, China.

We have more than 10 Year experience for manufacturing battery lab

research equipment. We own a professional R&D department.

2. Do you accept customized product?

A: Yes. Most of our products can be customized to meet different

requirements.

3. Will you provide test video before dispatch?

A: Yes, we take test video for every equipment before dispatch,

which will display how to use it.

4. Can you offer overseas installation service?

A: Yes, we can dispatch professional engineer for on-site

installation service.