Add to Cart

24/7 Process Operations - Distributed Control System- BJVP

Overview:

As the heart of plant-level digitalization, BJVP's Distributed Control Systems (DCS) are designed to transform your multi-faceted, 24/7 process operations. Our market-leading control architecture constantly monitors and drives plant productivity, maximizing asset utilization, process efficiency and production quality. A focus on availability, safety and cyber security ensures the protection of your people, assets and equipment. And by maintaining tight controls over raw material consumption, plant energy levels and waste by-products, BJVP DCS solutions help to significantly reduce environmental impact.

BJVP exceeds the needs of operators throughout the product lifecycle.With the international mainstream DCS as the core of the system, BJVP has developed a new generation of open-source factory automation control system for intelligent production/manufacturing: VPBATCH® and VPBLEND®.

VPBATCH® System:

VPBATCH® Batch Control System designed, developed and copyrighted by Beijing VP for Lube-Oil blending batch management.

VPBATCHE® Batch Control System suits for any Lube-Oil blending application can be connected to most mainstream of automation control system (DCS or PLC). VPBATCH® provides modular OP interface, flexile batch data configuration, open-source mode for recipe management. Batch configuration can be modified by on site operable no need to wait for processional systems engineer to modify various batch parameters. VPBATCHE greatly improves production efficiency of Lube-Oil blending.

Advantages:

1. Modular OP interface

2. Flexible batch data configuration

3. Multi-brand automation control system connection

4. Open-Source mode for recipe management

5. User-owned batch parameter settings

VPBLEND® System:

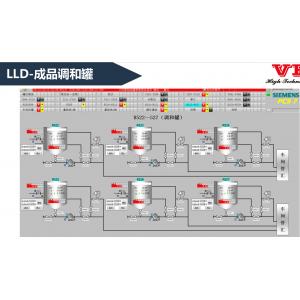

VPBLEND® Blending Control System designed and implemented by Beijing VP for Lube-Oil blending, product transfer and storage facility. VPBL ENDE application running on the Sever PC coordinates all real-time blend control algorithms running on the DCS, maintain configuration data, batch data, process runtime data and historian data.

VPBLEND® able to respond quickly to market demands, producing high-stand, quality products with significantly reduced manpower and inventory cost. VPBLEND® solutions specifically developed for the blending industries with the will to the company assets, to react quickly to customer demands with the permanent care of product quality and plant productivity.

Advantages:

1. Modular

2. Open Structure

3. Batch Management

4. Blending Process Monitoring

5. Quality Control

6. Intelligence Operation

Pictures: