Add to Cart

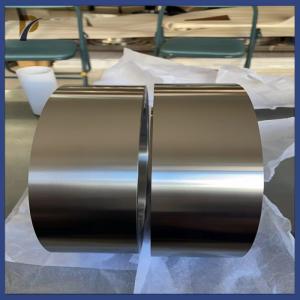

ASTM B265 Gr1 Gr2 Titanium Foil

1. Specification Of ASTM B265 Gr1 Gr2 Titanium Foil:

| Product Name: | Titanium Foil/Titanium Strip |

| Grade: | Gr1 Gr2 Gr5 Gr7 Gr9 Gr23 BT1-1 etc. |

| Density: | 4.51g/cm3 |

| Standard: | ASTM B265,ASME SB265,ASTM F136/67, AMS 4911,AMS 4905, AMS 4907, MIL-T-9046 |

| Surface | Bright |

| Thickness | min 0.01mm |

| Width | max 500mm |

| Process: | cold rolling |

Other grade and size can process according to customer's requirement. | |

2. Chemcial Composition Of ASTM B265 Titanium Foil/Strip:

| Element | Composition,% | |||||||||

| Grade1 | Grade2 | Grade3 | Grade4 | Grade5 | Grade6 | Grade7 | Grade9 | Grade11 | Grade12 | |

| N max | 0.03 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 |

| C max | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 | 0.08 |

| H max | 0.05 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 | 0.015 |

| Fe max | 0.2 | 0.3 | 0.3 | 0.5 | 0.4 | 0.3 | 0.5 | 0.25 | 0.2 | 0.3 |

| O max | 0.18 | 0.25 | 0.35 | 0.4 | 0.2 | 0.2 | 0.25 | 0.15 | 0.18 | 0.25 |

| Al | 5.5-6.75 | 4.0-4.6 | 2.5-3.5 | |||||||

| V | 3.5-4.5 | 2.0-3.0 | ||||||||

3. Features of gr1 gr2 titanium foil titanium alloy strip:

Lightweight and High Strength: Titanium foil has high strength and low density. It is less dense than other metals, such as steel and copper, yet has exceptional strength. This makes titanium foil useful in applications that require strength and light weight.

Corrosion resistance: Titanium foil has excellent corrosion resistance. It is resistant to corrosion by many chemicals, including salt water, acids, alkalis, etc. This makes titanium foil widely used in marine environment, chemical industry and other corrosive environments.

Good heat resistance: Titanium foil can maintain its mechanical properties and structural stability in high temperature environments. It has a high melting point (about 1668 ℃) and is able to work at high temperatures for a long time without failure.

Good thermal conductivity: Titanium foil has good thermal conductivity and can transfer heat quickly. This makes it useful in some applications that require high thermal conductivity, such as thermal management systems in aerospace.

Ease of processing: Titanium foil can be processed into various shapes and sizes by rolling, stretching, stamping and other processes. It has good plasticity and processability, and can adapt to different needs.

Biocompatibility: Titanium foil has good biocompatibility to human tissue and will not cause allergic reactions or rejection reactions. This makes titanium foil widely used in applications such as implant materials and artificial joints in the medical field.

4. Application Of ASTM B265 Titanium Foil :

Aerospace industry: ASTM B265 Titanium foil is widely used in aerospace field. It is used in the manufacture of aircraft structural components, engine components, combustion chambers, missile and satellite components, etc. Due to its light weight, high strength and corrosion resistance, titanium foil can help reduce the weight of aircraft and improve fuel efficiency.

Chemical industry: Due to its excellent corrosion resistance, titanium foil is widely used in the chemical industry to manufacture reactors, storage tanks, heat exchangers, pipes and valves and other equipment. Titanium foil can resist many corrosive media such as strong acid, strong alkali and salt water, so it plays an important role in the environment dealing with corrosive substances.

Medical field: Titanium foil is used in the medical field to manufacture implant materials and medical devices. It has good biocompatibility and biological inertia, and will not cause rejection of human tissues. Therefore, titanium foil is widely used in medical devices such as artificial joints, dental implants, bone plates and screws.

Electronics industry: Titanium foil is used in the electronics field to manufacture capacitors, batteries, shielding materials and connectors, etc. It has good electrical conductivity and corrosion resistance, which can meet the requirements of electronic devices.

Oil and gas industry: Titanium foil is used in the oil and gas industry to manufacture equipment such as offshore platforms, pipelines, and storage tanks. Due to the presence of seawater and corrosive gases, the corrosion resistance of titanium foil is crucial to prolong the service life of the equipment.

Art and decoration: Titanium foil is also widely used in the production of artwork and decorations. Due to its metallic luster and plasticity, titanium foil can be used to make jewelry, sculptures, decorative vessels, etc.

Company Profile:

Shaanxi Peakrise Metal Co., Ltd. is an rich experienced tungsten,molybdenum, tantalum, niobium, titanium,zirconium,nickel non-ferrous metal production enterprise,main products include tungsten-copper alloy, molybdenum-copper alloy, tungsten-molybdenum alloy, high specific gravity tungsten alloy, tantalum alloy,niobium alloy,titanium alloy and other more than 100 kinds of products.Products are exported to Taiwan, Ukraine, South Korea, the United States, Australia, Germany, Iran and other countries, and have established long-term good cooperative relations with customers. Our products are highly recognized and evaluated by customers.

Do you want to know more about our products?