Add to Cart

High Temperature Sintered Molybdenum Lanthanum Alloy Boat

1. Description of High Temperature Sintered Molybdenum Lanthanum Alloy Boat:

High-temperature sintered molybdenum boat is mainly used in vacuum furnace, and its operating temperature can reach about 1700-2000 ℃, mainly by doping a certain amount of rare earth elements in molybdenum powder to improve the high-temperature strength of molybdenum and expand the scope of use of molybdenum boat. The molybdenum boats used in the vacuum furnace industry are generally made of two materials: one is the molybdenum boat made of pure molybdenum, which can withstand high temperatures up to about 1100 degrees. The second is the molybdenum alloy boat produced by molybdenum lanthanum alloy and TZM alloy, which is used to meet the needs of higher temperature, and the high temperature resistance can reach about 1700-2000 degrees. The preparation process of molybdenum boat: by bending a molybdenum plate with a thickness of 3-6mm, and then using welding and riveting to make a molybdenum boat, generally called a welded molybdenum boat and a riveted molybdenum boat.

Molybdenum-lanthanum alloy, also known as high-temperature molybdenum, with the brand name MoLa, is a so-called laminated fiber structure formed by doping a small amount of lanthanum trioxide (La2O3) particles in molybdenum. This special microstructure remains stable at temperatures up to 2000°C. Therefore, even under service circumstances, molybdenum-lanthanum oxide exhibits creep resistance.

2. Chemical of High Temperature Sintered Molybdenum Lanthanum Alloy Boat:

| Grade | Main chemical content% | Impurity content(<%) | |||||||||

| Mo | Ti | Zr | C | La2O3 | C | 0 | N | Fe | Ni | Si | |

| Mo1 | Remain | — | — | — | — | 0.01 | 0.007 | 0.002 | 0.01 | 0.002 | 0.01 |

| TZM | Remain | 0.40~0.55 | 0.06~0.12 | 0.01~0.04 | — | — | 0.03 | 0.002 | 0.01 | 0.005 | 0.005 |

| MoLa | Remain | — | — | — | 0.4~1.2 | 0.01 | — | 0.002 | 0.01 | 0.002 | 0.01 |

Molybdenum Lanthanum Alloy Boat process according to customer's drawing.

3. Performance of High Temperature Sintered Molybdenum Lanthanum Alloy Boat:

(Unit:Ω*mm2/m)

| Temperature℃ | 20 | 600 | 1000 | 1200 | 1400 | 1700 | 1800 | 1900 | 2000 |

| Resistivity | 0.054 | 0.205 | 0.314 | 0.374 | 0.435 | 0.506 | 0.525 | 0.558 | 0.571 |

4. Advantage of High Temperature Sintered Molybdenum Lanthanum Alloy Boat:

1.)The recrystallization temperature is higher, the recrystallization temperature: 1400℃~1500℃. ;

2.)Elongated particulate structure for improved ductility;

3.)Stronger anti-oxidation;

4.)Higher creep resistance.

5. Craft of High Temperature Sintered Molybdenum Lanthanum Alloy Boat:

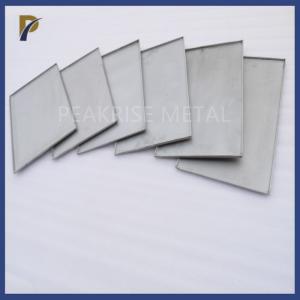

Rolling and Heat Treatment of Molybdenum Lanthanum Alloy Sheet

After the molybdenum-lanthanum alloy billet is opened at 1500 ℃, it is warmly rolled and cold rolled to a plate with a thickness of 2.4 mm. The pass processing rate is 25%~35%, and the total processing rate is 80%. The rolled molybdenum lanthanum plates were annealed in a hydrogen furnace at 1100, 1250, 1400, 1550 and 1950°C, respectively.