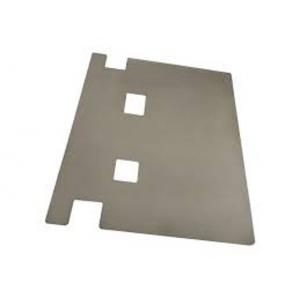

Structure Sheet Metal Assembly Punched Sheet Metal Welding Forming Parts

Add to Cart

Structure Assembling Punched Sheet Metal Welding Forming Parts Straight Supply

1 Sheet metal processing

Sheet metal, a processing technology, sheet metal has not yet a more complete definition. According to a

definition in a foreign professional journal, it can be defined as: sheet metal is for the sheet metal (usually

below 6mm) a comprehensive cold working process, including cutting, punching/cutting/composite, folding,

riveting, splicing, forming (such as automobile body).

2 Technical Parameters

| Product name | Structure Assembling Punched Sheet Metal Welding Forming Parts Straight Supply Sheet Metal Assembly |

| Item | Solenoid Valve Cover 3D Printing Sheet Metal Sheet Metal Assembly |

| Surface treatment | brushing, degrease etc, |

| Process | Punching, bending, |

| Tolerance | 0.06mm, |

| Service | OEM sheet metal fabrication, |

| Material thickness | 1.6mm, |

3 Product Details

Use: water purifier, home appliance

Function: this is in the bottom of the water purifier and it is a

structure part, this is one of the parts that we

made and we will assemble them together after all parts are

finished.

Technology: metal stamping, punch press, bending.

4 About Strong

Strong metal was established in June 2003 with a total registered capital of 67 million yuan and a total

construction area of 30,000 square meters. It has 5 factories in total which are located in Nantong,

Taicang, Nanjing, Vietnam, and Shanghai.

Strong has many advanced production equipments: 50+ punch press machines (highest 1000 ton),

20+plastic injection machines (highest 740ton), 20+ bending machines (highest 600 ton), 20+ automatic

welding arms, 50+ welding working tables, 8+ laser cutting machines, and a 400m powder coating line,

etc. In terms of the QC testing tool, We have CMM, a two-dimensional measuring instrument, hardness

tester, salty frog tester, etc.

Strong focused on metal manufacturing and has comprehensive ability in mold self-design, metal

stamping, sheet metal, laser cutting, powder coating, welding, plastic injection, etc.

5 FAQ

Q: What are your terms of payment?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance

before shipment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is

15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q: Are you a trading company or manufacturer?

A: We are a manufactory.

If you have another question, pls feel free to contact us.