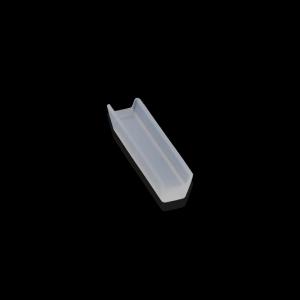

USP VI Class Food Grade Rubber Sealing Parts Injection LSR For ISO 8 Clean Room

Add to Cart

ISO 8 Clean Room Injection LSR Silicone Medical USP VI Class Food Grade Rubber Sealing Parts

Medical Rubber Parts Description

Medical rubber, a vital element in healthcare, refers to

rubber-based materials used for various medical applications. These

specialized rubbers are designed to meet stringent biocompatibility

and safety standards, making them suitable for use in medical

devices, equipment, and accessories. Medical rubber can be found in

components like O-rings, gaskets, seals, tubing, and connectors.

These materials must endure sterilization processes, resist

chemicals, and maintain their functionality over time. Their

properties ensure a reliable and hygienic environment, contributing

to the effectiveness and safety of medical procedures and patient

care.

Specification of Medical Rubber Parts

- Material: High-quality medical-grade rubber (compliant with biocompatibility standards)

- Shape: Various shapes, including O-rings, gaskets, seals, and custom designs

- Compatibility: Designed to work with a wide range of medical fluids and gases

- Sterilization: Resistant to common sterilization methods such as autoclaving, gamma radiation, and chemical disinfection

- Temperature Range: Capable of withstanding medical equipment operating temperatures

- Chemical Resistance: Able to resist a variety of medical-grade chemicals and solutions

- Durability: Long-lasting and reliable performance to maintain sealing integrity

- Compression Set: Minimal deformation after compression to ensure consistent sealing

- Biocompatibility: Meets international standards for safe interaction with biological systems

- FDA Compliance: Manufactured according to FDA regulations for medical devices

- Sizes: Available in a range of standard and custom sizes to suit various applications

- Tolerance: Precision manufacturing for tight tolerances and consistent dimensions

- Color: Typically translucent or black, but can be customized based on requirements

- Application Areas: Suitable for medical devices, surgical instruments, pumps, valves, connectors, etc.

- Certification: Depending on the application, may have certifications like ISO 13485 or ISO 10993

- Packaging: Sterile packaging options for maintaining cleanliness until use

- Assembly: Compatible with various assembly methods in medical device manufacturing

- Aging Resistance: Able to maintain sealing properties over extended periods

- Material Documentation: Material data sheets available for regulatory compliance and quality control

- Customization: Can be customized for specific performance requirements and applications.

Medical Rubber Parts Materials

here are some common materials used for medical rubber parts:

- Silicone Rubber: Widely used due to its biocompatibility, flexibility, and resistance to heat and chemicals.

- EPDM (Ethylene Propylene Diene Monomer): Offers excellent ozone and UV resistance along with good chemical compatibility.

- Nitrile Rubber (NBR): Known for its oil and fuel resistance, suitable for applications involving contact with medical fluids.

- Fluoroelastomers (FKM/Viton): Offers high temperature and chemical resistance, ideal for demanding medical environments.

- Hypalon: Known for its resistance to weathering, ozone, and chemicals, used in applications requiring durability.

- Natural Rubber (NR): Offers good flexibility and abrasion resistance, but may have limitations in some medical settings.

- Polyurethane (PU): Combines elasticity with chemical resistance, used in specialized medical applications.

- Butyl Rubber (IIR): Known for its air and gas impermeability, used in applications requiring sealing against these elements.

- Chloroprene (Neoprene): Offers a balance of resistance to oil, weathering, and ozone, suitable for various medical devices.

- Ethylene-Propylene Rubber (EPR): Combines good heat resistance with electrical insulation properties.

These materials are chosen based on the specific requirements of the medical application, including factors like biocompatibility, temperature resistance, chemical compatibility, and mechanical properties.

Medical Rubber Parts Application

| Application | Description |

|---|---|

| Surgical Instruments | Sealing components for precision surgical tools. |

| Pumps and Valves | Ensures fluid control and prevents leakage in medical pumps and valves. |

| Connectors and Tubing | Forms leak-proof connections in medical tubing systems. |

| Catheters | Provides sealing and protection in catheter assemblies. |

| Respiratory Equipment | Used in masks, valves, and connectors for oxygen delivery. |

| Infusion and IV Systems | Seals in infusion pumps, drip chambers, and connectors. |

| Diagnostic Equipment | Seals in imaging and diagnostic devices for accurate readings. |

| Dental Instruments | Used in dental devices to ensure sterile and safe operations. |

| Blood Management Systems | Sealing components in blood collection and analysis devices. |

| Implantable Devices | Ensures sterile environment in implantable medical devices. |

| Laboratory Equipment | Sealing in lab instruments and containers for accuracy. |

| Monitoring Devices | Used in medical sensors and monitors for precise readings. |

| Wearable Medical Devices | Provides waterproofing and sealing in wearable health tech. |

About Us

Splendid Rubber Products (Shenzhen) Co., Ltd. is located in Pinshan Town, Longgang District, Shenzhen City, Guangdong Province. Our Investment is 10 million RMB and the factory area is 10,000 square meters. With over 500 employees, our team works hard to maintain the highest standards of quality and serve the needs of our customers. At YuanMao (Splendid), our business philosophy is based on the principles of honesty, service, quality, hard work, fairness and team effort. Our main business focuses on the design, development, manufacture and the related mold development of rubber products. We mainly produce rubber molded parts, O-rings, and other rubber accessories. They are used for sealing valves of oil, air, and water or as the absorbers. We also offer custom molded products, which are manufactured by the samples from our customers. We have been certified by 2002-edition ISO/TS16949 from October 2003, we also got KTW, DVGW, WRAS, and NSF certifications for compound E7001Z59 in 2008. We have an extensive selection of materials available to meet ASTM, JIS, DIN, NSF, and other specifications. All of our products are backed by our ISO/TS16949 registered systems. Splendid meets TS16949 standards. Supporting documentation, PPAP control plans and FMEA are available upon request. We take quality very seriously; and that's our guarantee. ur compound N7001 is UL listed material --JML U2 We have cooperated with Trelleborg, Eriks, Parco, Mcmaster, Prosel etc. For many years, our turnover is over US$ 14 million.

FAQ

Q: Are you a manufacturer or a trading company ?

A: We're professional manufacturer of Medical Rubber Parts , providing one-stop OEM & ODM service to all partners all over the world.

Q: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the freight cost.

Q: What is your terms of payment?

A: T/T 50% as deposit, and bal.50% before delivery.

Q: What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.