Add to Cart

1. Description of solar panel support uni strut C channel roll forming machine:

Our factory is manufacturing high quality guardrail roll forming machines, and regularly exported to Australia, USA, Thailand, Canada,Turkey, Indonesia, Philippines, Malaysia, India, Angola, etc.

Solar Strut channel has been using for many years while installing solar power. The biggest advantage of solar strut channel is that it helps in the construction and easily connects the length together and other items, by using different strut fasteners.

This strut roll forming machine is for producing the strut channels which uses as the supporting frames of the solar panel. It is widely used in the solar industry.

There are standard dimensions for common uni strut channels, i.e. 21*41, 41*41 and 41*61, etc. And also there are punching holes continuously on the bottom of the channels for joints. The following are some regular joints or connections.

In addition, some other materials are also available for different applications. For instance, stainless steel will be used where rusting might become a problem (e.g., outdoors, facilities with corrosive materials), while the aluminum alloy is better material when weight is an issue or from fiberglass for very corrosive environments.

2.Technical details of solar panel support uni strut C channel roll forming machine:

| Machine Specifications | |

| Weight | About 8.5tons |

| Size | About 14.2mx1.3mx1.2m(length x width x height) |

| Color | Main color: blue or as your requirement |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 2.0-4.0mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 24 |

| Diameter of forming rollers shafts | 80mm |

| Roll Forming Speed | 15-23m/min |

| Forming rollers material | GCR15 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 11kw |

| Electric voltage | According to customer’s requirement |

3. Production Flows of solar panel support uni strut C channel roll forming machine

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

4. Main components of solar panel support uni strut C channel roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

5. Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

6. After-sell service

A. Foreign debugging

If you need it, we will arrange our professional engineers to help you install and debug the machines well. The buyer should pay $60 per day

B. Guarantee period

The warranty will be a maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during the guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t be forced by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

the buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation, and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.

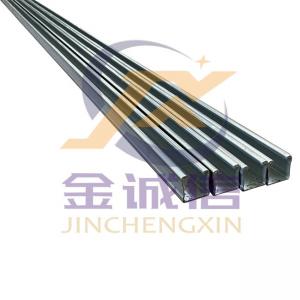

7. Product photo

8. FAQ

1. Does your company can customized my needed profile?