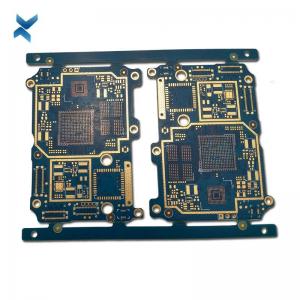

Audio Amplifier Multilayer PCB Circuit Board Fabrication Volume Production

Add to Cart

Audio Amplifier Multilayer PCB Circuit Board Fabrication Volume Production

Bare Board Fabrication PCB Volume Production For Audio Amplifier

Advantages of Multilayer PCBs

What do these factors mean when deciding between a multilayer and

single layer construction?

Essentially, if you're looking to produce a small, lightweight and

complex device where quality is essential, a multilayer PCB is

likely your best choice.

However, if size and weight are not primary factors in your product

design, then a single or double layer PCB design may be more

cost-effective.

YS Multilayer PCB manufacturing capabilities overview | ||

Feature | capabilities | |

Layer Count | 2-60L | |

Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

buried and blind via | ||

Hybrid | High Frequency Material such as RO4350B and FR4 Mix etc. | |

High Speed Material such as M7NE and FR4 Mix etc. | ||

Thickness | 0.3mm-8mm | |

Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

BGA PITCH | 0.35mm | |

Min mechanical Drilled Size | 0.15mm(6mil) | |

Aspect Ratio for through hole | 10:1 | |

Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

Copper filled, silver filled | ||

Registration | ±4mil | |

Solder Mask | Green, Red, Yellow,White, Black, Purple, Matte Black, Matte green.etc. | |

layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

FQA

Q: What is impedance control in PCB design?

A: Impedance control is the process of maintaining a consistent

electrical impedance throughout the length of a trace on a PCB. It

is important for high-speed signals to prevent signal distortion

and ensure signal integrity.

Q: What is the lead time for manufacturing a PCB?

A: The lead time for manufacturing a PCB can vary depending on the

complexity of the design and the chosen manufacturing process, but

typically ranges from a few days to a few weeks.

Q: What is the difference between through-hole and surface-mount

technology (SMT)?

A: Through-hole technology involves inserting electronic components

through holes in the PCB and soldering them in place. SMT involves

attaching components directly onto the surface of the PCB using

solder paste and a reflow oven.

Q: What is the purpose of a solder mask on a PCB?

A: The solder mask is a protective layer that is applied to the PCB

to prevent solder from accidentally bridging between adjacent pads,

shorting out the circuit, and causing electrical problems. It also

helps to protect the PCB from environmental factors such as

moisture and dust .

Q: What is the purpose of a silk screen on a PCB?

A: The silk screen is a layer of printing that is applied to the

surface of the PCB to label components and provide other

information such as the company logo, part numbers, and test

points.