Add to Cart

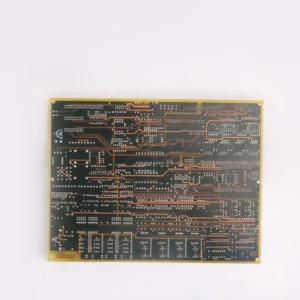

The GE DS200TCQCG1BJF is an Analog IO Expander Board (TCQC) integral to the Mark V LM Series within GE’s Speedtronic Control System. It enhances the system’s capability to process additional analog signals from I/O core terminal boards, handling scaling, conditioning, and distribution of critical data for turbine operation. Key functions include providing excitation for LVDTs/LVDRs, terminating IONET connections, and processing megawatt transducer signals—scaling them before transmission to the STCA board via the 19PL connector. It also conditions pulse rate inputs and exchanges generator/line signals with the STCA board through the JE connector, making it vital for seamless turbine control.

Key Features:

Comprehensive Signal Processing & Distribution

The board excels in managing diverse analog signals, it scales and

conditions megawatt transducer inputs, pulse rate signals, and

generator/line data. It routes processed signals to critical

components—sending shaft speed/flow data to the TCQA board via JE

and megawatt signals to the STCA board via 19PL. Additionally, it

provides excitation for LVDTs/LVDRs, ensuring accurate position

sensing essential for turbine actuation.

Servo Valve Control Circuitry

Dedicated circuits manage servo valve regulation, jumpers scale

current from the TCQA board to position valves, with reference

feedback and current ranges set via hardware. The board integrates

servo clamp relays applying positive current to valves and suicide

relays grounding signals to let valves drift to bias positions.

Suicide relays activate via signals from the CSP routed through the

TCQA board, ensuring safe, controlled valve operation during fault

conditions.

IONET Integration & System Compatibility

It hosts IONET termination for specific cores when the optional

21> is installed, enhancing communication within the Speedtronic

system. Its standardized connectors ensure seamless interaction

with the STCA and TCQA boards, maintaining signal integrity across

the control architecture. This integration is critical for

synchronizing turbine subsystems, from sensors to actuators.

Tailored for Turbine-Specific Needs

By focusing on high-pressure shaft speed, liquid fuel flow, and

servo valve control—parameters vital to gas/steam turbine

performance—the board addresses industry-specific demands. Its

ability to condition and route these signals with precision

supports efficient turbine operation, reduces response latency, and

enhances overall system reliability in power generation and

industrial settings.