Add to Cart

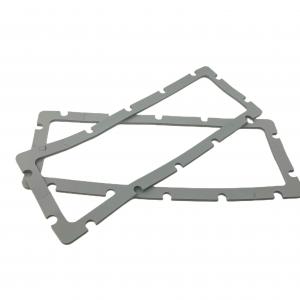

Battery Pack Sealing Gasket Pack Seal Silicone Silicone Foam Flame-Proof Rubber Gasket Silicone Foam Gasket Tape

Silicone foam insulation has emerged as a superior solution for battery protection and thermal management systems in the rapidly evolving field of new energy vehicles (NEVs). This article delves into the inherent advantages of silicone foam insulation, highlighting its unique capabilities and why it surpasses traditional materials. By understanding its benefits, we can explore its critical role in enhancing NEV battery performance, safety, and longevity.

Excellent Resilience:

Silicone foam insulation boasts exceptional resilience, making it

an ideal choice for battery protection. Experimental data reveals

that even after undergoing 8,000 cycles of compression, the

material experiences minimal deformation, with less than 5% change.

This outstanding rebound property ensures long-term effectiveness

and reliability, safeguarding NEV batteries throughout their

operational lifespan.

Comprehensive Prtection:

Silicone foam insulation provides more than just insulation. It

offers additional advantages, including dustproofing,

waterproofing, heat dissipation, and shock absorption. These

properties are pivotal for NEV battery protection systems,

shielding the battery pack from external contaminants, preventing

moisture ingress, efficiently managing heat generated during

operation, and minimizing the impact of vibrations and shocks. Such

comprehensive protection contributes to the overall performance,

safety, and durability of NEV batteries.

Unyielding Performance under Extreme Conditions:

Silicone foam insulation undergoes rigorous testing to evaluate its

performance under harsh environmental conditions. Experimental data

from stress relaxation tests conducted at 85°C and 85% relative

humidity for 1,000 hours demonstrates that the material exhibits a

stress relaxation rate of only 20.98%. This exceptional result

attests to its ability to maintain mechanical integrity and provide

consistent performance, even in demanding situations. NEV batteries

can rely on silicone foam insulation to deliver unwavering

protection, regardless of challenging operating conditions.

Superior Compression Resistance:

Silicone foam insulation has excellent resistance to crushing and

retains its shape and performance even after extensive use. The

material exhibits a consistently low compression set, ranging from

0.34% to 0.72% in a 10,000-belt 1 million compression cycle test,

ensuring its long-lasting durability and effectiveness in

protecting new energy vehicle batteries.

These results highlight the material's resilience and ability to maintain its shape and performance, even after prolonged use. NEV batteries benefit from the long-lasting durability provided by silicone foam insulation.

Minimal Water Absorption:

Silicone foam insulation exhibits an impressively low water

absorption rate of only 0.266%. This characteristic is crucial in

NEV battery protection, as it ensures the material remains stable

and unaffected by moisture. The low water absorption rate prevents

any adverse effects on the battery pack's performance, even in

humid environments. It further reinforces the material's

suitability for NEV applications.

As the NEV industry continues to advance, silicone foam insulation emerges as the optimal choice for battery protection and thermal management systems. Its exceptional resilience, comprehensive protection features, unyielding performance under extreme conditions, superior compression resistance, and minimal water absorption set it apart from traditional materials. Silicone foam insulation plays a pivotal role in enhancing NEV battery performance, safety, and longevity. Its numerous advantages make it a compelling solution that should be widely adopted in the NEV industry, driving innovation and ensuring the continued success of new energy vehicles.

Sealing Effectiveness and Compressibility

Assembled housings or enclosures must ensure adequate gasket compression to provide the required level of seal. This compressibility enables the load to remain within required limits while accommodating a larger range of compressions. The seal or gasket needs to conform specifically to its surfaces, whether an aircraft, automobile or industrial enclosure. If the gasket leaks requires replacement, enclosure certification can be lost, resulting in lost time and increased expenses in addition to the damage incurred to the components. PORON® Polyurethane and BISCO® Silicone foams are highly compressible and conformable, effectively sealing for the life of the product. Both are available in a wide range of firmness and thickness options to ensure robust sealing design.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Application

| Example Gasket Application | Properties |

| High Temperature | Silicones can perform well in an extremely low and high-temperature range from -103° F to 450° F. |

| Weatherproofing | This gasket material is resistant to ageing and degradation from sunlight and ozone. |

| Automotive | Closed-cell silicone is resistant to many chemicals and meets many industry flame retarding specifications. |

| HVAC Sealing & Mechanical Seals in Equipment Access Panels | The closed cell structure provides air and moisture barriers under ambient conditions.s |