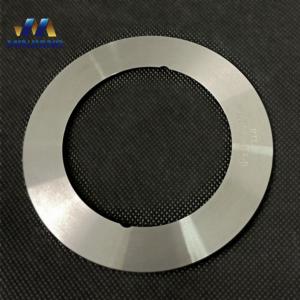

Product Details

Tungsten Tipped Hardened Cutting Blades for Cutting Wood

Achieve precise and efficient cutting with our Tungsten Tipped Hardened Cutting Blades. These Tungsten Tipped Hardened Cutting Blades are designed for use with rotary cutting tools and feature sharp

tungsten carbide edges that maintain their cutting performance even

with frequent use. Suitable for cutting fabrics, leather, paper,

and more, our rotary cutter blades ensure clean and accurate cuts,

making them an essential tool for sewing, quilting, and crafting

enthusiasts.

Modle

| Model NO. | Sizes | Applicable machine |

| F0001 | 220*115*1-3*9 | Agmari |

| F0002 | 230*110*1.1-6*9 | Fosber |

| F0003 | 230*135*1.1 | Fosber |

| F0004 | 240*32*1.2-2*8.5 | BHS |

| F0005 | 240*115*1-3*9 | Agmari |

| F0006 | 250*150*0.8 | Peters |

| F0007 | 257*135*1.1 | Fosber |

| F0008 | 260*140*1.5 | Isowa |

| F0009 | 260*168.3*1.2 | Marquip |

| F0010 | 270*113*1.25 | Egypt |

| F0011 | 280*202*1.4 | Mitsubishi |

| F0012 | 291*203*1 | Mitsubishi |

Our Advantages

- Profession: Minjiang is a cutting-edge, privately-owned enterprise

that specializes in the manufacturing of cemented carbide tools.

With a strong focus on technological advancements, we excel in

producing high-quality tools that cater to a wide range of

industrial applications.

- Product Lines: Our company boasts a diverse range of professional

equipment, enabling us to offer a comprehensive production line

dedicated to the manufacturing of hardened cutting blades. This

integrated system ensures the efficiency and precision of our

production processes, allowing us to meet the varying needs of our

customers.

- Production Capacity: Presently, our company comprises a dedicated

workforce of 100 skilled employees, operating within a sprawling

10,000 square meter facility. Moreover, we are currently in the

process of constructing a state-of-the-art factory, equipped with

cutting-edge technology and infrastructure. This expansion project

exemplifies our commitment to enhancing production capacity and

meeting the growing demands of the industry.

- Quality Control: At Minjiang, we prioritize delivering consistent,

high-quality products to our customers. To guarantee this, we have

established a team of experienced inspectors who oversee every step

of the production process, from raw material acquisition to final

inspection. By implementing rigorous quality control measures, we

ensure that our products adhere to the highest standards, providing

our customers with reliable and durable tools that exceed their

expectations.

Supply At Source

- Quality: Buying products directly from the source factory ensures

that the products are of the highest quality as they come from the

source of production.

- Price: Eliminates the middleman and thus, reduces the cost of the

product.

- Timeliness: Ensures that the products are delivered in a timely

manner without any delay.

- Customization: Allows customers to customize their orders to meet

their specific needs.

- Relationship: Allows customers to build a relationship with the

factory, thus ensuring better customer service.

Package

Company Profile

Chengdu Minjiang Precision Tool Co., Ltd., founded in 1992, is a

high-tech private enterprise at the forefront of producing CNC

carbide cutting tools, oil pipe thread cutters, carbide wear parts,

and carbide non-standard products. Spanning across 10,000 square

meters, our facility accommodates four cutting-edge work plants,

each equipped with professional machinery. As a holder of the

ISO9001:2008 quality management system certification, we guarantee

the supply of high-quality products with exceptional efficiency and

possess the capability to develop innovative solutions to cater to

diverse customer requirements.

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a manufacturer.

2. Q: Do you offer customized products?

A: Yes, we often make customized products.

3. Q: Do you provide free samples?

A: We can provide free samples, but do not undertake the freight

cost.

4. Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is

20-35 days if the goods are not in stock, it is according to

quantity.

Company Profile

Chengdu Minjiang Precision Cutting Tool Co. Ltd, based in Chengdu, Southwest China, is a leading provider of

high-end wear-resistant parts and precision cutting tools.

Minjiang has been a leader in the industry for the last 30 years

and is committed to providing high-quality products to clients. Our

extensive portfolio of products is designed to provide maximum

efficiency and performance while minimizing wear and tear. Our

commitment to product development and quality improvement has

enabled us to stay at the forefront of the industry for decades.

Through continuous development, we have now formed a complete blank

production line, a finished product production line, and a complete

inspection system, and has passed ISO9001:2015 quality management system certification. Now we are dedicated to

the development and production of tungsten-carbide wear parts and bearings, oil pipe thread tools,

CNC tools, lithium battery slitter blades, and other customized

products.

We have cultivated a team of experienced engineers that work with

cutting-edge technology to ensure that the clients benefit from the

highest quality products and services. The company’s commitment to

excellence is evident in the rigorous quality control measures and

the dedication to providing customized solutions to fit the needs

of the clients. With our focus on quality and reliability, we

strive to be a trusted partner for our clients.

We believe that quality is key to our success and thus we strive

for excellence in everything we do. We are committed to providing

our clients with products that are reliable, safe, and efficient.

Moreover, we are also dedicated to providing our customers with the

best customer service possible.

We look forward to working with you and helping you find the right

products for your needs.

FACTORY

EXHIBITIONS

QMS CERTIFICATE

AWARDS