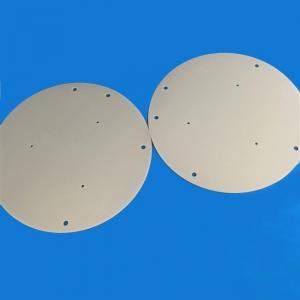

Round Alumina Ceramic Plate Industrial High Alumina Substrate

Add to Cart

Round Ceramic Plate Industrial High Alumina Substrate In Electrical Ceramics

Industrial High Alumina Substrate In Electrical Ceramics

Main characteristics of alumina ceramic substrate

1. Good thermal shock resistance, greater than 220 T(ºC)

2. High thermal conductivity of high purity alumina, up to 30 W/m.k

at 25ºC

3. Good surface roughness, flatness to be 0.05mm with min. warpage,

deformation

4. High dielectric strength, low dielectric constant, and

dielectric loss.

5. Laser cutting or precision machining cutting makes tight

tolerance.

The specification of the ceramic substrate

1. Materials: 96% alumina, 99% alumina, 99.5% alumina, zirconia,

silicon nitride, silicon carbide optional

2. Dimensional capability: the side length to be 500mm x 600mm, the

thickness can be 0.15mm to 30mm

3. Surface treatment: lapping, fine ground, diamond-like polished

to be Ra0.05, metallization, glazed

The description of alumina ceramic substrate

We have been making alumina (Aluminum oxide, Al2O3) ceramic

substrate for over 12 years under rigorous quality control with

carefully selected high purity ceramic materials ranging from 95%

to 99.8%.

All these alumina sheets offer extraordinary properties of

electrical insulation, thermal conductivity, breaking strength, and

high-temperature resistance. Furthermore, one of the unique

properties is its superb surface roughness to be Ra0.2 which

results in excellent adhesion strength with a thin film and thick

film metallization due to fine particles, also it can play a very

important role in the sintering process which work as alumina

ceramic setter.

The regular forming methods we use include tape-casting, isostatic

pressing, dry pressing. We are dealing with a variety of selection

of thicknesses from small-size to large-size capability. With our

comprehensive types of manufacturing types of equipment, we have

the capability from prototyping to mass production in the short

term.

The checklist of alumina ceramic sheets in stock

| Size (Unit: mm) | Thickness | |||

| 132 x 142 | 1.0 | 0.635 | 0.80 | |

| 114 x 114 | 1.0 | 0.635 | 0.80 | 0.385 |

| 109 x 130 | 1.0 | 0.635 | 0.80 | |

| 109 x 109 | 1.0 | 0.635 | 0.80 | |

| 287 x 87 | 0.635 | |||

| 395 x 83 | 1.0 | |||

| 122 x 120 | 1.0 | 0.80 | 0.50 | |

| 109 x 120 | 1.0 | 0.635 | 0.80 | |

| 138 x 190 | 1.0 | 0.635 | 0.80 | 0.50 |

| 127 x 127 | 1.0 | 0.635 | 0.80 | |

| 280 x 240 | 1.0 | 0.635 | 0.80 | |

Remark:

All the above ceramic sheets can be cut as per customers' detailed

specifications.

Related products of technical ceramic sheets