Product Details

Easy Operation Metallographic Image Analysis Software MetaVision

for Metallurgical Microscopes

Technical Data Download: iqualitrol Metallurgical Analysis Software MetaVision

Brief Introduction:

Application Program are set in the simplest way without

compromising accuracy so that inexperienced operator can also make

analysis with a minimum of training.

Our current portfolio of metallurgy solutions are Nodules analysis,

Coating Thickness Measurement, Depth of Width Measurement of

Decarburization, Phase percentage with display by colored overlays,

Grain Size No., Porosity Analysis, Graphite Flakes Measurement,

Non-Metallic Inclusion Rating, Particle Size and Volume Percentage

with lot make software complete.

Generated reports can be saved or printed with images, Histogram,

Data Overlays colors and various other related information.

MEASUREMENT

- Spatial calibration

- Line measurements for Distance, Length, Width, Perimeter, Angle,

Three Point Radius.

- Area by enclosed line controlled by four arrow keys available on

keyboard arrows with zoomed preview.

LIVE MEASUREMENT

- Live Measurement can handle monochrome (8 bits) and color (24 bits)

images. Multiple images of any size can be opened and displayed on

the screen for analysis or comparison. The software support most

common formats BMP, JPEG, TIFF, PNG, GIF & PSD. The live image can

be observed and captured on the same platform. And the software

also support Measurement On Live Images. Live measurements for Line

, Ellipse , Rectangle , Circle , Center Circle , 3 Point Circle , 2

Line Angle , 3 Point Angle, Center to Center, Parallel line

Perpendicular line , Point to Point Horizontally, Point to Point

Vertically , Poly line ,Perimeter , Curved Area , Curved Length ,

Perpendicular Distance, Min Distance, Max Distance, Circle to Point

and Chord.

COUNT AND CLASSIFICATION

- Identification of objects in an image, count them, obtain several

features measurements. Objects identification by user or

automatically. User defined classification on basis of size or

intensity.

THRESHOLD PARTICLE MEASUREMENT

- Manual, Auto bright and Auto dark methods to identify intensity

range defined object to be measured. Various calculation &

measurements available for selected Particle are; Dimensions, Area,

Perimeter, Feret Length, Min/Max Radius, Thread Length, Thread

Width, Fibre Length, Fibre Width.

MORPHOMETERY

- Roundness, Shape, Orientation, Elongation, Equal Circular Diameter,

Equal Sphere Volume.

LOCATIONAL

- Centroid X, Centroid Y, Major X1, Major Y1, Minor X1, Minor Y1,

Major X2, Major Y, Major X2, Minor Y2, Box X1, Box X2, Box Y, Box

Y2 & Box Area.

PHASE

- Measure area fraction & volume fraction. Identify multiple phases

within Microstructure. Also delineate phases from the histogram as

per ASTM Standard E562 & E1245.

NODULES

- MEASURE Nodularity as per ASTM 247 standard. The Nodules & Flakes

are separated on the basis of its shape and aspect radio.

The detail measurement of each microstructure is available for

further analysis. The processed image displays non-Nodules in

different color. The Nodules can be classify by its range on the

basis of its size & shape.

POROSITY

- They are recognized on the basis of its intensity as per ASTM B-276

standard. The measurement of each pore is displayed. The processed

image displays pores in Red color.

CASE DEPTH

- ASTM ISO 2639-02, BS-6479-84, IS-6416-88 JIS G0557 DIN 50790. The

test determine the depth of hardened surface under low

magnification by measuring the distance from the surface to the

point shaving a different coloration towards core

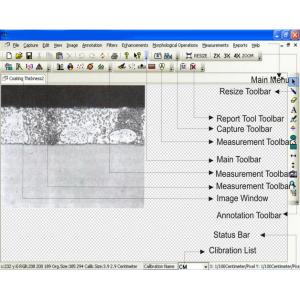

COATING THICKNESS

- This application rapidly measures the thickness or width of a

coating at multiple positions along a sample as per ASTM B487

standard. Tabulated results available for min/max and mean of width

measured at various points of sample cross section.

DECARBURISATION

- Measured depth or width of decarburisation occurs as per ASTM 1077

standard.

GRAIN SIZE

- The module analyze Grain image and measure the Grain no. & Grain

size using ASTM E 112 , JIS G-551, E-930, E-1181, ISO 643-03, BS

490 DIN 643-03, IS-4748-88, SIS 111101 GOST 5639-82 The options for

measurement available are 1. Manual Trace, 2. Popular Comparison

Method, 3. Quick single Grain measurement, 4. ALA method, 5.

Interception method. Various filters to make user defined

templates. Grain boundary repair mathematical function.

NON METALIC INCLUSION

- Measure inclusions and report ASTM E-45, E-1245 AND DIN-50602, JIS

G-552 numbers, cumulative length, width ratio.

GRAPHITE FLAKES

- Graphite Flakes length, width, distribution and percentage as per

ASTM A-247-67, ISO 9451-1, DIN EN 945-94, BIS 7754 JIS G5504,

IS-7754

SG IRON ANALYSIS

- The module automatically analysed & calculate Nodulanty/Non

Nodulanty percentage. Determine its class and number from 1 to 8 as

per ASTM, JIS, BIS & ISO standard s, Nodules per square mm is also

on Etched sample it reported. Determine percentage of pearlete,

graphite, ferrite and carbide.

CAST IRON ANALYSIS

- The dedicated module determines flake size from 1 to 8 as per ASTM,

JIS, and BIS & ISO standards. The type distribution percentage A,

B, C, D, E is calculated interactive tools. Flakes per square mm is

also calculated simultaneously.

REPORT

- Three options: Direct printout with original image processed Image

& Tabular results

- Export to MS Office or Excel for further modification.

Company Profile

iqualitrol is a professional company to supply quality control

instrument and repair service. The main products are industrial

video borescope, hardness testers, metallographical instrument,

metallurgical microscopes, temperature test chambers, etc.

These are widely used in machinery, mold, metal, rubber,

connectors, household appliances, printed circuit boards, medical

equipment, and so on.

Our sales and service staff are well trained and experienced. They

can give professional advice to customers and recommend suitable

equipment according to specific requirement.