Add to Cart

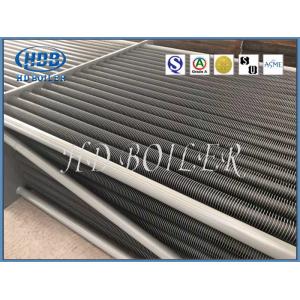

Steel Power Plant Economizer / Boiler Economizer Heat Exchanger With Automatic Or Manually TIG Argon Arc Welding

Economizer Description

Economizers are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid.

The term economizer is used for other purposes as well. Boiler, power plant, heating, Refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article.

In simple terms, an economizer is a heat exchanger.The economizer

has advanced manufacturing technology, strict production

technology, detection means, with high-tech snake-like tube

production lines.

Parameter

| Name(unit) | Specification(mm) |

| Bare pipe(OD) | 25-165 |

| Bare pipe(Thickness) | 2-8 |

| Fin (Thickness) | 0.6-3.0 |

| Fin (Height) | 5-30 |

| Fin tube thread pitch | 5-30 |

| Fin tube length | ≤12000 |

*Note:HD BOILER can bespoke special type of economizer according to

customer's requirement.

Details

| 1 | Economizers must be sized for the volume of flue gas, its temperature, the maximum pressure drop allowed through the stack, what kind of fuel is used in the boiler, and how much energy needs to be recovered. |

| 2 | Economizers designed for natural gas only, would likely plug-up if installed on a coal boiler and would face increased risk of corrosion if installed on an oil-fired boiler. |

| 3 | Some units are designed to keep the flue gases above condensation temperature, and others are made of materials that resist the corrosive effect of condensed flue gases. |

Application

| 1 | During boiler operation in typical commercial and industrial applications, approximately 10-20% of the heating value of fuel is expelled with the stack gases to the atmosphere. |

| 2 | Stack economizers are designed to recover significant amounts of this stack gas energy loss, thereby vastly improving boiler system efficiency. |

| 3 | There are several considerations when selecting an economizer |

| 4 | Gas-side Pressure Drop. Added back-pressure on the boiler stack affects the combustion air fan throughput capability. The economizer and combustion air fan(s) must be sized properly in order to assure a suitable system operation and capacity. |

| 5 | Feedwater Temperature. The feedwater to the economizer must be deaerated and the temperature setpoint minimally at 220oF to prevent tube corrosion. |

| 6 | Water-side Pressure Drop. Feedwater pumps must be sized to accommodate the economizer pressure drop. Additionally, a continuous modulating feedwater system is required to ensure proper flow rates through the economizer. |

Quality Control

| 1 | Impact test and Strength calculation report with applied materials information. |

| 2 | 100%NDT(non-destructive inspection) report of steel plate, tube and electrode. |

| 3 | X-ray, γ-ray and liquid penetrant test inspection report (welding seam): to ensure the quality of the entire boiler. |

| 4 | Hydraulic test report: ensure the standard working pressure and safety. |

Certification

Company Introduction

Established in 1985,Zhangjiagang Hua Dong Boiler Co.,Ltd.(trading

as HD Boiler),produces power plant; industrial; waste heat; waste

incineration; biomass; organic heat carrier and electric steam

boilers. Coupled with a comprehensive range of heating surfaces, HD

Boiler brings to the market a unique service including boiler

design , fabrication, installation, maintenance and replacement of

boiler pressure parts.

• Fabrication area of 200,000 square meters

• 80 Engineers

• 200 Coded welders

• 30 Licensed Inspectors(NDT Level-III instructors)

• Class-A Licenses for Design and Manufacture Boiler

• ISO 9001:2015 Quality System

• ASME Certificate of Power Boilers

• ASME 'S','U' and NB stamp authorization