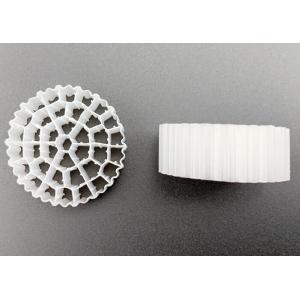

White Color HDPE K1 Filter Media PE37 For Water Quality Improving

Add to Cart

MBBR bio media Round pipe white color china manufacturer K1 filter media

Product introduction:

MBBR is a moving media system, used in Integrated Fixed-lm Activated Sludge (IFAS) and moving bed biofilm reaction (MBBR) system. The wastewater goes through suspending media of MBBR reactor, forming biological membrane on the surface of media gradually. With the action of microbial on the biological membrane, wastewater is purified. MBBR biofilm carrier can move freely in the reactor with the mixing of the water. For the aerobic reactor, the aeration will make the media move; for the anaerobic reactor, mechanic mixing will make the media move. Our MBBR biofilm carrier is new-developed media, has better treatment effect compared with traditional media.

Main feature:

Special formula and production technology, accelerating biological

film formation ;

Larger effective surface area, obtaining more microorganism;

By bio-film decomposing technology, saving sludge return process;

High-efficiency in denitrification and dephosphorization, improving the water quality;

Lower energy consumption, saving space and shorten technology process.

Specification:

| Model | Size(mm) | Specific Surface Area(m2/m3) | Bio-film formation Duration (days) | Nitrification Efficiency | Preferential Temperature (ºC) | Services life(years) | Number of unites per m3 |

| PE37 | Φ25×10 | >800 | 5-15 | 400-1200 | <65 | ≥20 | >118,000 |

Small Boss MBBR Biofilm Carries

We supply a range of biofilter media, This product is sold by the

cubic metre. These products are suited to fluidized or moving bed

tank systems. These are also called "Biofilm Reactor (MBBR)"systems

and are used for treatment of water and wastewater.

Self cleaning due to turbulence:

Due to the turbulent movement of the biofilter media in

suspension,the filter media is self-cleaning ,requiring no

maintenance.This allows the filter to reach optimum effeciveness

without the disturbance of periodic maintenance,avoiding

unnecessary loss of bacteria within the filter.This allows

stable,low levels of ammonia and nitrite within the water.

The first few of these products are similar to the patented kaldnes

media used in fish farming and waste treatment .The design creates

an environment for effective nitrification to take place .Twater

flow is created by aeration tha circulates the media throughout the

vessel .This high suface area of these products traslates into a

small physical area needed for the biofiltration unit.

Due to vigorous mixing of the kaldnes-like media through

aeration,the media is self-cleaning,Requiring no maintenance.This

allows the filter to reach optimum effectiveness

Periodic maintenance is not necessary,preventing the unnecessary

loss of bacteria and subsequent ammonia and nitrite spikes in the

system.

Media volume needed:

with good turbulence and aeration, a feed rate of between 0.25 kgs

and 0.75 kgs of 40% protein food per day requires 50 litres of

media.