Add to Cart

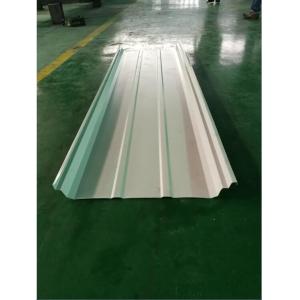

0.6 - 0.8mm Standing Seam Roof Panel Roll Forming Machine fix in 40GP Container

Saibo Standing Seam Metal Roofing Sheet Cold Roll Machine is design

to make the cost-effectively cladding and roofing large round or

conical buildings.

Saibo Standing Seam Metal Roofing Sheet Cold Roll Machine features

for your reference:

1.Roll forming, solemn and elegant, beautiful and novel, smooth

appearance, uniform ripple, high utilization rate, high strength,

high production automation, low cost and durability.

2.Save material , no waste

3.The automation control system adopts a highly integrated network,

and the automation system has superior performance.

4.This machine also has the advantages of easy operation,

maintenance, maintenance and debugging of machinery and mold

replacement.

1. Specification of the material

| 1 | Suitable Material | PPGI,PPGL Yield strength 320-400Mpa |

| 2 | Width of the raw material | 760mm |

| 3 | Thickness | 0.6-0.8mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | Standing Seam Roll Forming Machine |

| 2 | Machine structure | Wire-electrode cutting frame |

| 3 | Total power | Motor power-7.5kw Hydraulic power-5.5kw |

| 4 | Roller stations | About 13 stations |

| 5 | Productivity | 0-20m/min |

| 6 | Drive system | By chain |

| 7 | Diameter of shaft | ¢70mm solid shaft |

| 8 | Voltage | 380V 50Hz 3phases (Customized) |

| 9 | Color Of The Machine | Bule and yellow |

| 10 | Deliver time | 70 days |

| 11 | Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

4. The Chart of Process Flow

Manual Decoiler—Roll Forming—Cutting—Out table

5. Specification of Components

(1) Un-coiler

(2) Main Roll Forming Machine

(4) Hydraulic station

(5) Computer Control Cabinet

6. Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

C.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.