Shanghai Beyond Machinery Co., Ltd, as a private business started

in the year of 2005, is a specialized technology-oriented machinery

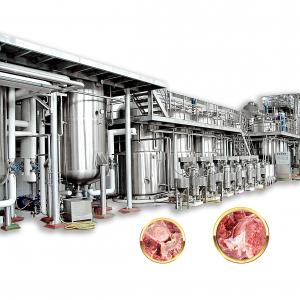

manufacturing enterprise. Beyond specializes in the turn-key

projects of the design, manufacture, installation and commissioning

for the production lines of liquid food such as dairy, drink, ice

cream, fruit and vegetable, bio-engineering, chemical and

pharmaceutical.

Cooperated with several domestic and abroad Light Industrial or

scientific research institutions, we absorb their advanced

technology and then take base to develop new even better process

techniques, we are now specializing in all kind of sanitary tank,

pot, container, heater, cooler, sterilizer, concentrator, pump and

other pipe and fittings.The equipments are in accordance with the

relative standards of Juice, Dairy, Pharmacy, bio-chemical, such as

HACCP, QS and GMP.

Through the years of the common efforts of our staff, we have

obtained high share in the market of machinery industry, and have

developed ourselves into a medium-sized enterprise of certain

popularity in the industry. Combining scientific research,

technical development, production, marketing and after-sale

service, we keep ourselves acting strictly in accordance with the

quality assurance system of ISO 9001.

Production range:

Processing Machinery For Various Fruits and Vegetables

Conveyor and elevator series

Washer and sorter series

Pulper and crusher series

Evaporator and deaerator series

Stainless steel tanks series

CIP cleaning series

Crate washing machine

Various Fruits and Vegetables Production Lines

Complete unit of citrus processing line, include orange, lemon,

pomelo, grapefruit etc.

Complete unit of Chinese date/Jujube and hawkthorn processing line

Complete unit of sea-buckthorn processing line

Complete unit of peach / apricot and plum processing line

Complete unit of pineapple / mango and other tropical fruits

processing line

Complete unit of tomato processing line

Complete unit of apple/pear processing line

OUR MANAGEMENT PHILOSOPHY:

Reputation from quality;

Trust from sincerity;

Praise from specialization;

Development from innovation;

Social benefit from corporate benefit;

OUR CORPORATE CULTURE

Customer-oriented: We seek for success by exceeding customer requirements. We

emphasize on clearly understanding customer requirements to provide

first-class customer service. We offer high-quality products and

service through the formula developing and manufacturing of

products. We honor our commitments by offering after-sale service

and technical support. The contact with customers every time is an

opportunity for us to win customer satisfaction and to create new

business chance.

Honest Operation:

As a corporation and an individual, we always do what is right. To

be honest is the basic principle for business activities. We

conduct ourselves honest in behavior and business. Honesty is

regarded of the same importance as life in our company, and this

value system has always been placed as a supreme objective by us at

any time. We respect our agreements and contracts and value high

honesty in communication. The relationship with colleagues,

customers, suppliers, investors and banks is established on the

basis of openness and seeking for common interests. Our sense of

responsibility extends to caring on working environment and

atmosphere, and bringing up the style of everyone being

professionally dedicated.

Commitment Honoring:We commit ourselves to providing satisfactory products and service

to customers, well-deserved reputation to suppliers, ideal returns

to investors, extensive promotion and common development

opportunities for staff, and good social benefits to the society.

To honor commitments is the sole criterion of success.

Development from Management:We keep in mind that the maximized benefit comes from scientific

management. Only by introducing in talented managers and advanced

management philosophy can we continuously improve the level of

enterprise management. And only by combining the characteristics of

our company to create a set of scientific and distinctive

management system complying with the characteristics of our company

can we remain invincible in the furiously competitive market.

Unceasing Improvement:No matter what great success we have accomplished in respect of

products, service, personnel training and management etc., we will

always commit ourselves to making them better in the way to adopt

new viewpoints and better working patterns, and to bear the

responsibilities and risks therefore resulted. We encourage our

staff to hold the enthusiasm of reformation and the thirst for

knowledge in everyday work, and to share their working experience

with colleagues, so as to accomplish the success of individuals and

excellence of company.

People Oriented:The professional, career-respecting, cooperative and enterprising

personnel are basis for BEYOND development. And it makes all

personnel exert their self-independence and creativities fully,

through building up perfect and highly effective inspiration and

restriction system, and put personnel usage concepts of “Competence

determines talents, comp-etition creates talents,achievements

evaluate talents” into effect.

Appoint Talents as per Capabilities and to Proper Positions:“Appoint Talents as per Capabilities and to Proper Positions”,that

is,not only to appoint proper talents to proper positions,but also

to “Know talents,tolerate talents, use talents and cultivate

talents”and to design development orientation for talents through

“H-pattern”talent development route.

Advanced equipmentd:Advanced automatic producing equipment, Polish pipeline work, show

first-class quality.The technical expert participates in the

production directly to guarantee product stable and reliable. The

day by day growing high-quality goods consciousness and

continuously industry goods will make our making equipment to

change with each new day.No matter how the world changes, strives

for perfection is our invariable spirit.