Add to Cart

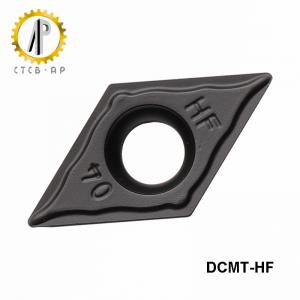

DCMT11T3 Tungsten Carbide Inserts Cutting Tools Machine Cast Iron With High Stability

What is tungsten carbide inserts?

Cemented carbide are classified according to their composition and can be classified into tungsten carbide-based hard alloys, titanium carbide-based hard alloys, coated hard alloys, steel-bonded hard alloys, and other hard alloys (such as chromium carbide-based hard alloys).

Excellent chip control for cast iron machining . Provides perfect turning surface of the workpiece:

Models introduction for Cast Iron machining:

| HF | HM |

| DCMT070202 | DCMT070204 |

| DCMT070208 | |

| DCMT11T304 | |

| DCMT11T308 |

Different chipbreakers:

Grades recommendation:

YC330 | For finish machining of steel at high speed | CVD coating |

YC331 | The most versatility grade of steel processing | CVD coating |

YC332 | For rough machining of steel parts | CVD coating |

Contrast Advantage/Benefits of choosing our carbide inserts:

1. CVD coating: Al2O3 and TiN coating.

The coating helps to decrease the temperature associated with the cutting process and increase the life of the tool.

2. High hardness (86.5~93HRA, equal 69~81 HRC)

3. Excellent edge strength

4.Short production cycle

5. High wear resistant

6. High impact resistant

7. High Temperature Resistance/Great High Temperature Performance

Customer’s case: when a insert is failed on performance:

1. Flank Wear

-Workpiece material contains high hardness chemical elements (tool

steel, die steel)

Increase cutting speed if abnormal flank wear is caused by a very

slow cutting speed.

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

2. Crater Wear

-Workpiece material contains high hardness chemical elements

Solution: Reduce cutting speed or feed rate or use more wear

resistant grade

3. Cracking

-Excessive feed rates when interrupted cutting

Solution: Reduce feed rate, Use tougher grade

Quality control:

Technical support and after-sale service:

1: We recieve deposit.

2: We provide free samples to customer, but buyer should bear freight.

3: Our company provide good after-sale service and technology support, If any quality problem is proved to be our responsibility, you can return the product in full and give it to you.

4. OEM: According to the requirement, supply neutral packing, without label and marking.

Tool holder:

S08K-SDQCR/L07

S10K-SDQCR/L07

S12M-SDQCR/L07

S16Q-SDQCR/L07

S20Q-SDQCR/L11

S25R-SDQCR/L11

S32S-SDQCR/L11