Add to Cart

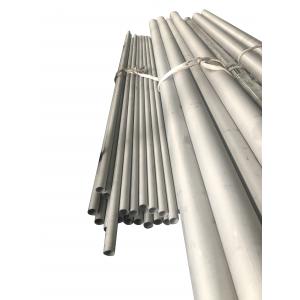

SA312 TP317L Best quality 317l Stainless Steel Tube and SS UNS

S31703 Seamless Pipe

Stainless steel 317l belongs to a low carbon austenitic grade. It

is produced via the extrusion process where heated steel billets

are passed through the metal creating a hollow opening. The

Stainless Steel 317L Pipe is designed with a chemical composition

consisting of iron, chromium, nickel, molybdenum, manganese,

silicon, phosphorous, carbon, and sulfur. The content embedded in

them allows these modules to possess enhanced corrosion and

oxidation resistance properties across stress-induced environments.

Stainless Steel Grade 317L Pipe works well in aqueous conditions

due to the content of molybdenum within them. The lower carbon

content also allows them to be resistant to sensitization and gives

them higher creep-rupture properties. The 317l stainless steel

tubing is non-magnetic in the annealed condition. They can be

readily welded in place following standard procedure. The grade can

be dual certified by the addition of a strengthening agent like

nitrogen in its composition. The tubes cannot be heat treated but

are usually cold worked to harden them in the system.

Applications:

317L stainless steel Pipes are suitable for vertical organizations

for boiler units, construction industry, heat exchangers units,

chemical & Fertilizer production, surgical instruments, power

generation plants, Chillers & Cooling system, engineering oil and

gas and shipbuilding, for onshore & offshore industries,

exploration, Pulp & Paper Defense, Industry, LNG, fasteners,

Desalination, Aerospace, Automobile, Cross Country Pipe Line for

sugar industry, Gas & Water, Nuclear and Solar Power Plants,

Thermal, Sewage & Waterwell Industry Atomic Energy, hydrocarbon

process.

Description for our production range:

Name :Stainless Steel seamless Pipe

Standard :EN10216-5 , EN10216-2,DIN 17456 , DIN 17458,ASTM A312,

A213, A269, A511, A789, A790 ETC,GOST 9941 , GOST 5632,

JIS G3459 , JIS G3463,GB/T14975,GB/T14975, GB13296, GB5310, GB9948

| Grade Specifications For 317L Stainless Steel Pipe | ||

| STANDARD | UNS | WERKSTOFF NR. |

| SS 317 | S31700 | 1.4449 |

| SS 317L | S31703 | 1.4438 |

Material Grade :

TP317L

Diameter :OD: 6-830mm

W.T: 0.6mm - 60mm

Length :Up to 13 meter or as customers' request

Tolerance :According to the Standard.

Surface :

Natural Color of annealing & pickling, 180G, 320G, 400G Satin /

Hairline

400G, 500G, 600G or 800G Mirror finish

Test :

UT, ET, HT, RT,ect, and others according to the standard,

or as the requests of the customer

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 317L | min. | – | – | – | – | – | 18 | 3.0-4.0 | 11 | – |

| max. | 0.08 | 2 | 1 | 0.04 | 0.03 | 20 | 15 | – | ||

our products packing:

other supplement:

1.A999/A999M: Each pipe shall be subjected to the nondestructive

electric test or the hydrostatic test, the pipe of test to be used

shall be at the option of the mfg, unless otherwise specified in

the PO.

2. The Pipe lengths : Unless otherwise agreed upon, all size from

NPS 1/8" TO AND INCLUDING nps 8 are available in a length up to

24ft with the permitted range of 15 to 24 ft. Short length are

acceptable and the number and min, length shall be agreed upon

between mfg and purchaser.

3. The finished pipe shall be reasonably straight and shall have

workmanlike finish, Removal of imperfections by grinding is

permitted, provided the W.T are not decreased to the less than the

permitted in Section 9 of Specification A999/A999M

4. Butt Weld End: According to ANSI B 16.25

5. Pipe Marking: Specified in A999/999M, include

"Logo+Standard+SIZE+Heat No.+Lot No.+H.T/E.T/U.T"

6. Packing: Each Pipe end is protected by Plastic cap. Then packed

by Anti-rust steel strip, The outside of the bundle is plastic

woven bag, or Plastic film.

7. Packing Mark: SIZE + STEEL GRADE+ QTY OF PIECE/WEIGHT/METRE.

8.MTC: BWSS Official Original MTC paper will be supplied for each

order.