Add to Cart

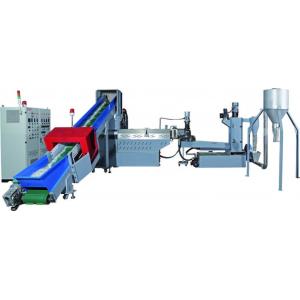

PP, PE, PET Plastic Recycling Pellet Machine With Special Screw Design

Plastic Recycling Pellet Machine Introduction

Film washing line is widely used to treat PP/PE plastic waste mixed material into clean film flakes,which include agriculture film, waste industry film, house refuse films, ton bags, PP woven bags and so on. After films cleaned, you can make them to be granules with next process which is called pelletizing line.

The production line is mainly used for granulation of recycled plastics. With special screw design and different configurations, it is also suitable for the regeneration and mixed color granulation of PP, PE, PET, PS, ABS, PA, PVC, PC, POM, EVA, PMMA and other plastics.

Single screw, double screw (flat double, cone double) can be used according to the user's requirements or feeding characteristics.The main machine is equipped with dewatering device, which can directly process waste plastic with water, simple and efficient.

Plastic Recycling Pellet Machine Main Features:

Plastic Recycling Pellet Machine Functions:

This plastic pelletizing machine can be displayed "L" or "U" shape according to clients' workshop.

Compacting force feeder

Function: With multi blades crushing and forcedly compressing the material into the extruder.

Single Screw Extruder (first stage):

Function: Plasticizing material with high temperature and exhausting hot gas and moisture.

Single Screw Extruder (second stage)

Function: Further plasticizing and filtering material with high temperature.

PP PE film pelletizing line

Single stage Main Technical Parameter:

| Model | STML65 | STML85 | STML 100 | STML130 | STML160 |

| Screw Dia. | 65 | 85 | 100 | 130 | 160 |

| L/D Ratio | 33:1 | 33:1 | 33:1 | 33:1 | 33:1 |

| Capacity (kg/h) | 60-100 | 150-250 | 200-350 | 400-500 | 500-600 |

| Compactor Motor (kw) | 22 | 37 | 55 | 90 | 110 |

| Extruder Main Motor (kw) | 37 | 55 | 90 | 132 | 185 |

| Total Electric Power(kw) | 110 | 150 | 205 | 300 | 395 |

Detailed Pictures