Add to Cart

Continuous spot welding service for OEM manufacture

Quick Details:

| Laser welding: | 4 Axis |

| Min laser welding point : | 0.20 x 0.20mm |

| Processing range: | Laser welding, laser marking |

| Materials: | Full series of stainless steel, Platinum-Iridium alloy, Ni & Ti alloy, Copper |

Description

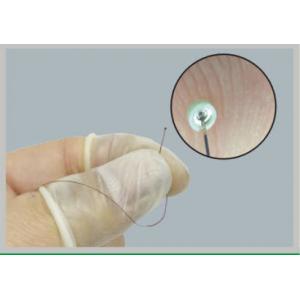

When the laser pulse is focused into one place - a small spot -

(adjustable anywhere from approximately 0.02 to 1.0 mm

(0.001"-0.040") in diameter) on the part, the power density is

sufficient to cause rapid melting to create the weld. The high

power density enables efficient absorption of the laser by creating

the "keyhole effect." As the pulse ends, the liquified metal

resolidifies and creates a small spot weld. This entire process

happens in just a few milliseconds.Laser spot welding is a process which uses a laser to create a

single weld spot to join metals together. Lasers are capable of

delivering a precise pulse of light with accurate, repeatable

power, energy and duration.

Competitive Advantage:

Quality Assurance

Jenitek is committed to supplying products and services that meet the needs of customers, comply with statutory and regulatory requirements, increase customer satisfaction and maintain the effectiveness of the quality management systems through continuous improvement in products, processes and services.

Jenitek's quality management system has been certified ISO 13485:2012 and ISO 9001:2008 in order to fulfill each of our customers' specific requirements.

We have a thorough quality system including four levels of documentation including manuals, procedures, work instructions and records. According to system documentation and processes, our quality activities such as production, inspection, product development (NPI), process validation, supplier chain control, and continuous improvement are controlled. This means we can deliver precision, performance and safety products and services to our customers around the world.

6 Sigma Quality Team

The Jenitek quality team understands these system standards are not only the foundation of quality management but also paramount to the importance of our medical products, customers and product development, production, and improvement process. We have extensive experience with quality management and use a range of methods and tools, including IQ/OQ/PQ, FMEA, PFMEA, and Design of Experiments (DoE) to support in product development and improvement processes.

Packing and Tracing

Products with validated sterile packing. Specifically configured to meet stringent packing validation requirements.

Certification

ISO 9001:2008 Certified

ISO 13485:2012 Certified

ISO 14001:2004 Certified

OHSAS 18001 Certified